Combined winding "Slavyanka"

About the combined winding technology "Slavyanka"

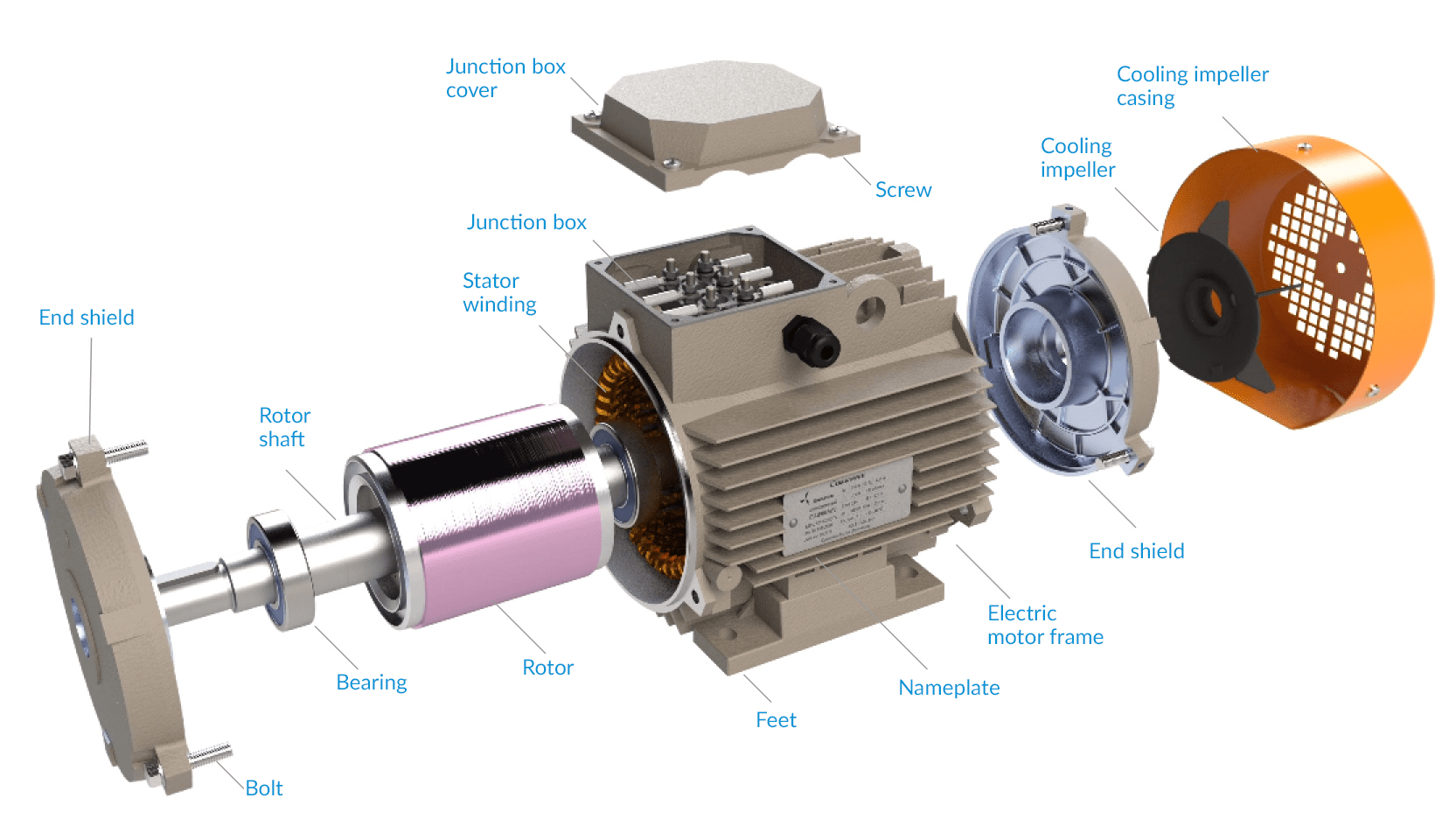

The combined winding technology "Slavyanka" is applicable for most types and kinds of electrical rotating machines, both single-phase and three-phase ones. In their classic version, these motors are designed with either a "star" or "delta" winding.

The peculiarity of "Slavyanka" is combining two winding types in one electric motor. "Star" and "Delta" are combined in parallel with a 30-electrical-degree shift of the resultant electromagnetic induction vectors.

The combined winding was named "Slavyanka". Motors with this winding type have unique performance features and outperform all the world rivals available in the market.

關於其他技術詳情,請前往:「Sovelmash」網站。

Advantages of electric motors with "Slavyanka"

Improved energy efficiency class

Scope of application

-

電動腳踏車

-

Electric mopeds

-

Electric motorcycles

-

Electric cars

-

Public transport

-

電動機車

-

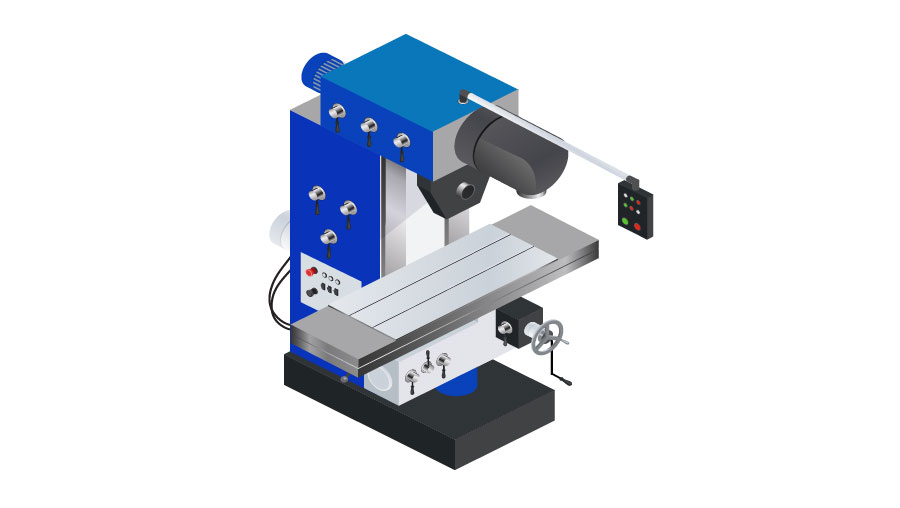

Machine tools

-

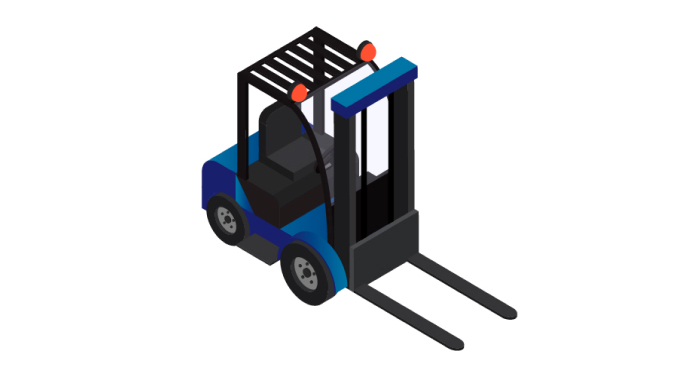

起重設備

-

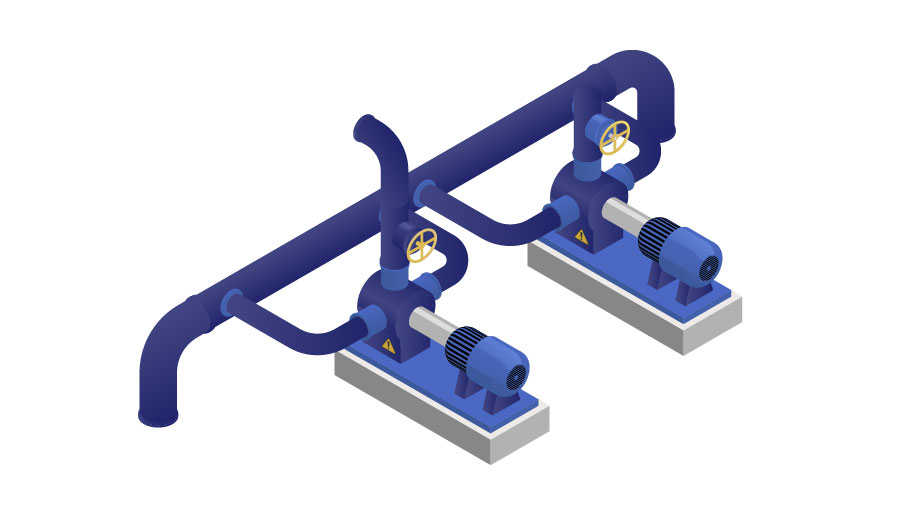

幫浦

-

Ventilation

-

Crane equipment

-

Conveyor belt lines

-

Wind turbines

-

Hydroelectric power plants

-

Thermal power stations

-

Nuclear power plants

-

Mobile power generating units

-

Renewable energy industry

-

Fridges

-

Washing machines

-

Vacuum cleaners

-

Dishwasher

-

Ventilators

-

Microwave oven

-

Agricultural equipment and machinery

-

Construction equipment and machinery

-

Medical equipment

-

Ships, yachts, motor boats

-

Military equipment

-

Aviation

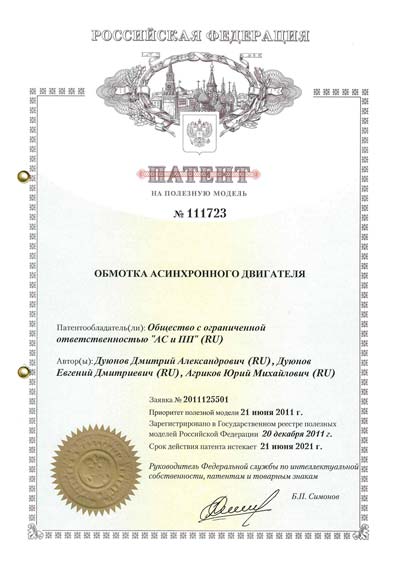

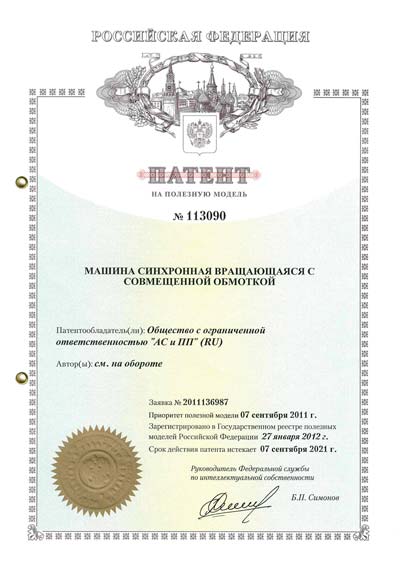

專利

Studies of electric motors with "Slavyanka"

-

University Düsseldorf, 2016

Comparative tests of the general purpose industrial motor rewound by applying the "Slavyanka" technology. University Düsseldorf

Independent tests of general purpose industrial motors were conducted in the Higher School at University Düsseldorf.

The task was to test the original motor and then rewind it using the "Slavyanka" technology, test the modernized motor and compare the results.

A 7.5 kW motor was provided for the tests. The tests demonstrated that after the "Slavyanka" technology modernization it: <br>- had a 30% bigger torque, <br>- consumed up to 30% less electrical energy.

You can view the test reports here - https://clck.ru/G7VX9

-

University of Bologna, September 2013

Comparative tests of the "Slavyanka"-rewound motor. University of Bologna, September 2013

The task of the test was creating a combined winding motor for electric buggies based on the "Slavyanka" technology and conduct comparative testing of it against the standard motor.

The standard motor made specially for the buggy weighed 54 kg and had a copper rotor. A general purpose industrial motor weighing 27 kg with an aluminium rotor was chosen for testing the "Slavyanka" technology.

Its performance characteristics: 4 polar size-100 AEG motor, 3 kW, with 86% efficiency and IE2 energy efficiency class. For the tests, the controller developed at the University was used that synchronized perfectly well with the motor rewound using Duyunov's technology.

The tests were conducted in three different modes: • nominal 135 A, • 270 A, • 350 A.

As a result, the modified motor fell short by 1 kW of the nominal power and by 1 kW of the maximum power. The previous motor for electric buggies produced the power of 20 kW at 350 Amperes, and 19 kW - with the combined winding.

There were differences in the efficiency values too: the electric buggy motor - 91%, the modified general-purpose industrial motor with "Slavyanka" – 89%.

Victor Arestov, who was running the tests, admitted that the choice of motor for the tests was not fully correct. To achieve the planned results, a size 112 motor should have been chosen instead of a size 100 one to, with a higher power of 4 kW.

However, it should be taken into consideration that the weight difference of the motors was almost twofold, and the special motor for electric buggies had a copper rotor while the modified motor had an aluminium one (by replacing the aluminium rotor with a copper one, you can increase efficiency by 2-3%).

At the same time, the 27-kg combined winding motor demonstrated almost the same performance as the specially developed original motor weighing 54 kilograms!

You can view the test reports here - https://clck.ru/GQgTM

-

Belgorod University, 2016

Comparative tests of induction electric motors. Belgorod University, 2016

Belgorod State Technological University hosted comparative tests of two induction electric motors AIR 71V4.

The goal of the procedure was checking the stated performance of the motor AIR 71V4 modernized using the "Slavyanka" technology as compared to a similar factory-manufactured motor with the standard three-phase winding.

In the course of the tests, reduced noise level and heating temperature of the modified motor was noted. The tests demonstrated considerable performance improvement of the modified electric motor in virtually all operational modes as well as improved efficiency in a wider load range.

It was concluded that in the process of real-life operation, the combined winding motor would enable significant reduction of power consumption by 14-20%. The largest saving amount could be achieved in the electric drive operation modes with the motor load lower than nominal. Besides, reducing starting and nominal currents, decreasing the operational temperature of the stator winding, reducing the internal conductor vibration in the coils and stator slots would considerably slow down the rate of conductor insulation wear.

The researchers recommended the "Slavyanka" technology for repairing induction electric motors at industrial enterprises with the purpose of considerable energy saving.

The test report is available here https://drive.google.com/file/d/1e6RKjKRkJq28NUDDz8i216c6ES_5HbIB/view

-

Belgrade quarry, 2015

Testing the motor with "Slavyanka". Belgrade, October 7, 2015

The goal of the tests was to determine how the electric motor performance changed after replacing the traditional winding with the "star-delta" combination.

The Serbian company D.O.O. «Savian» received a 15 kW induction electric motor with a burnt winding for modernization. The motor had been used in a rock quarry. The motor owner, the company D.O.O. Kuevo, ordered a full-fledged repair that included changing the winding type.

As a result of applying the energy-saving "Slavyanka" technology, the modernized motor performance changed as follows.

The nominal power increased from 15 kW to 19 kW, i.e., by 26.6%.

No-load currents were not detected before the repair, since the motor was inoperable. According to the motor certificate, the value was 27 A, and after modernization it decreased to 13.4 A.

The conducted tests graphically demonstrated the energy efficiency of the "Slavyanka" technology. Chief Technology Officer at D.O.O. Kuevo confirmed the operational reliability of the modernized motor.

You can view the test report here https://drive.google.com/drive/u/0/folders/1H5tQwSIQX9siP_J_-t9zf6bCMGaQ9Nq5?ths=true

-

Russian plant, July 2016

Tests of the modernized motor for a drain pump. Russia, July 2016

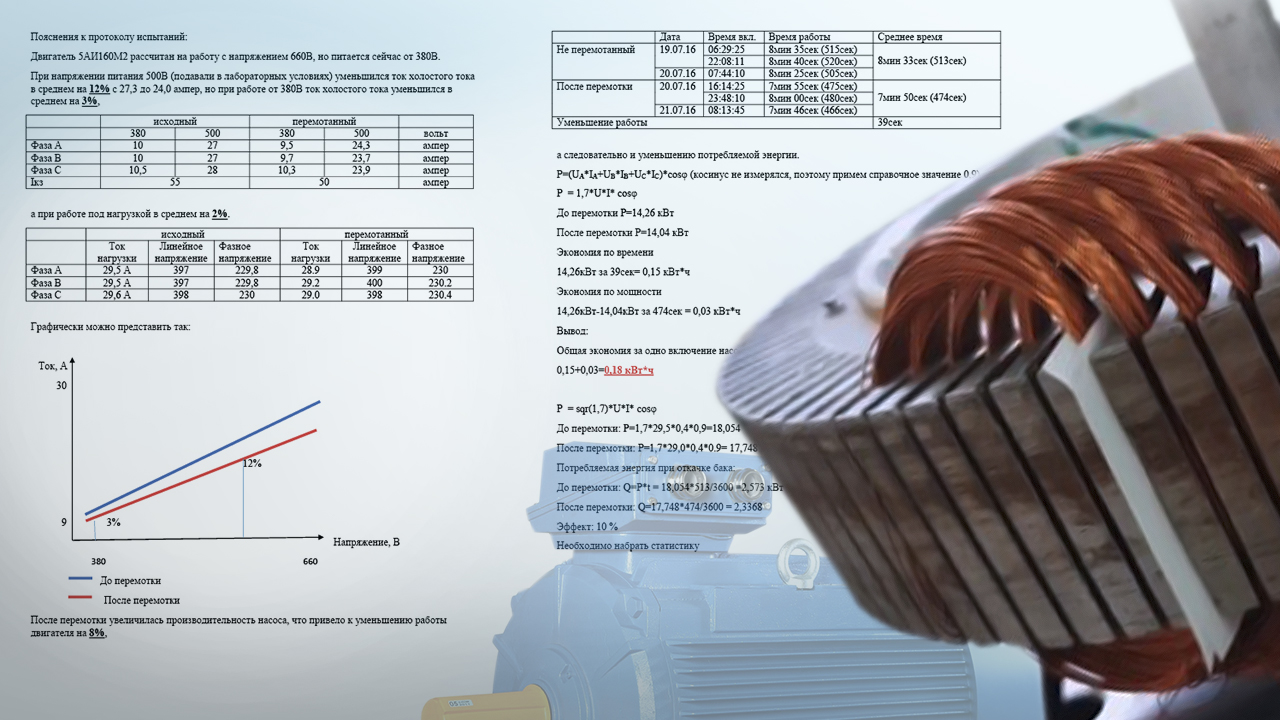

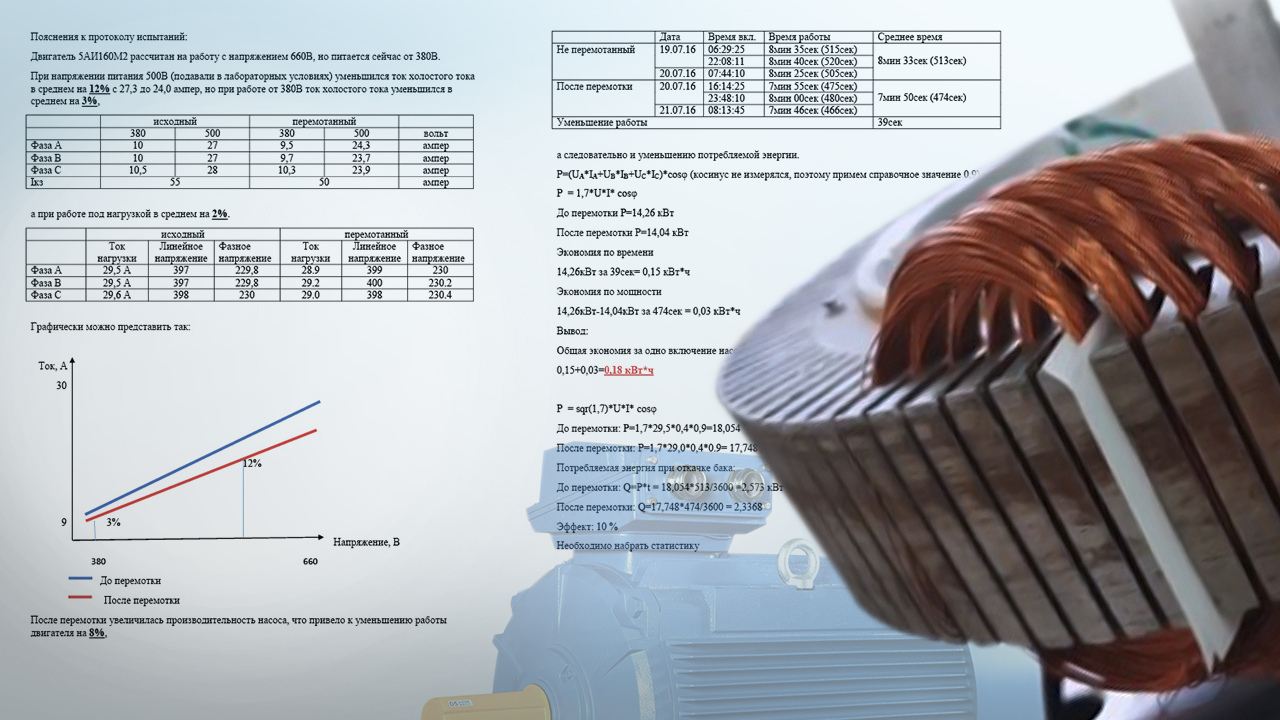

Engineers of the Russian plant modernized the induction electric motor 5AI160M2U2 with the power of 18.5 kW installed in a drain pump. During the repair, the blown old winding was replaced by burning, and the motor was rewound using the patented "Slavyanka" technology.

The goal of the tests is to identify changes in the motor performance characteristics after modernization.

Before the repair, the 5AI160M2 motor was designed to operate at the voltage of 660V, after modernization it was powered from 380V mains electricity. At 500V supplied in the laboratory conditions, the no-load current reduced on average by 12% (from 27.3 A to 24.0 A). When operating at 380V, the no-load current reduced by 3%, and under load — by 2%.

After rewinding, the pump productivity increased (duration of the pump operation cycle reduced by 39 seconds). It resulted in reduction of the required motor operation time by 8%. The total energy saving per one motor switch-on amounted to 12 %. The consumed power when draining the tank before rewinding was 2.573 kW, after rewinding it decreased to 2.3368 kW. The saving was 10%.

The test results confirmed the efficiency of the combined winding technology "Slavyanka".

The test reports and explanations for them are available here https://drive.google.com/drive/u/0/folders/1a1fglrN6zxjGJ1b7o3DLrUbMPJgn13PJ?ths=true

-

The Saint Petersburg Metro, October 2015

Tests of the motor modernized using the "Slavyanka" technology. The Saint Petersburg Metro, October 2015

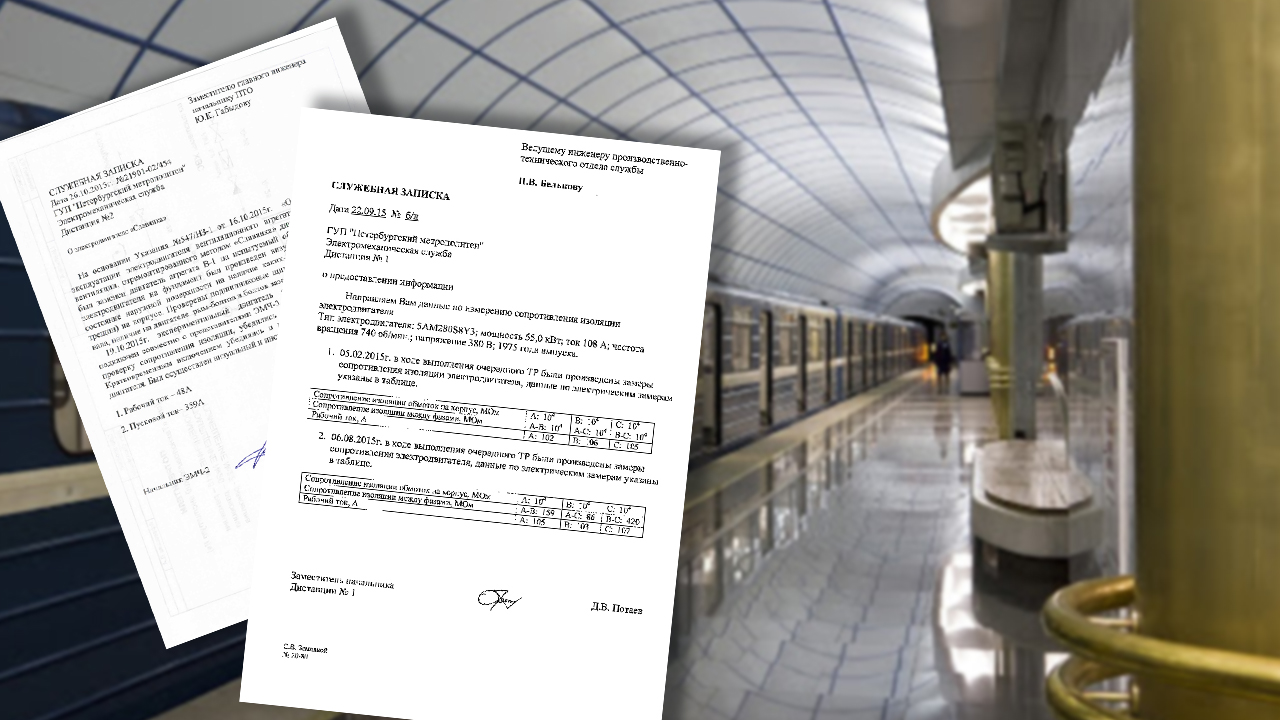

At the request of the production technology department of the Saint Petersburg Metro, the workers of electromechanical service modernized an inoperable electric motor of a ventilation unit in a powerful tunnel ventilation system by applying the energy-saving "Slavyanka" technology.

The goal of the tests was to identify the changes in the performance characteristics of the motor after modification.

The type of the repaired electric motor produced in 1975 — 5AM280S8Y3. Its power before the breakdown was 55 kW, current — 108 A, speed — 740 revolutions per minute, voltage — 380 V.

After the repair, the experimental motor was installed in V-1 unit. As a result of the tests, the commission determined the following performance characteristics of the modernized motor with the "Slavyanka" winding: the running current was 48 A; the starting current amounted to 359 A.

The tests confirmed that modernizing electric motors using Duyunov's technology increased their energy efficiency.

The document clarifying the course and results of the tests is available here https://drive.google.com/drive/u/0/folders/1ful8GH2DhtwOOA8p2cGIc3J3OxRrXRkd?ths=true

-

Russian plant producing ventilation systems, 2016

Comparative tests of electric motors. Plant producing ventilation systems, Russia, October 2016

The goal of the tests is to compare the performance of two induction electric motors AIR80A4 with the winding types "Star" and "Delta".

The test results of the modernized combined winding motor compared to a regular motor demonstrated a reduction of the consumed motor power due to almost complete absence of the reactive component.

As a result of applying the energy saving technology "Slavyanka" the electric motor performance

changed in the following way:

- the power factor increased from 0.77 to 0.99;

- with the shaft load increased, the consumed power grew from 1.1 to 2.23 kW;

- the maximum temperature of the "Slavyanka" motor frame was 74°С

with the admissible temperature for thermal resistance of class "F" winding insulation equal to 105°С.The recorded 2.2 kW power of the modernized motor is nominal for similar-type motors with 4 pairs of poles and rotation axis length of 90 mm, i.e., the next step of the size scale.

Test report is available here https://drive.google.com/file/d/1ImngEFWJFqXGn_FZh2rvYCgemDfrve_S/view

-

2019 年「Sovelmash」綠城實驗室

正在測試這兩顆電動馬達:DA-90S 和 DA-100S L。2019 年「Sovelmash」綠城實驗室

「Sovelmash」實驗室執行馬達的工作台測試,在 AS & PP 威海市針對以下兩顆馬達,進行現代化測試:DA-90S 和 DA-100S L(長期)。

The goal of the tests was to confirm the stated performance of electric motors.

The tests returned expectably good results.

Both motors demonstrated the efficiency of up to 90% in the nominal mode, and within a wide torque range the efficiency was 85-88%. The motors successfully withstood long-term overloads of up to 60 N·m.

Test report for DA-90S motor - https://clck.ru/FVG4q

-

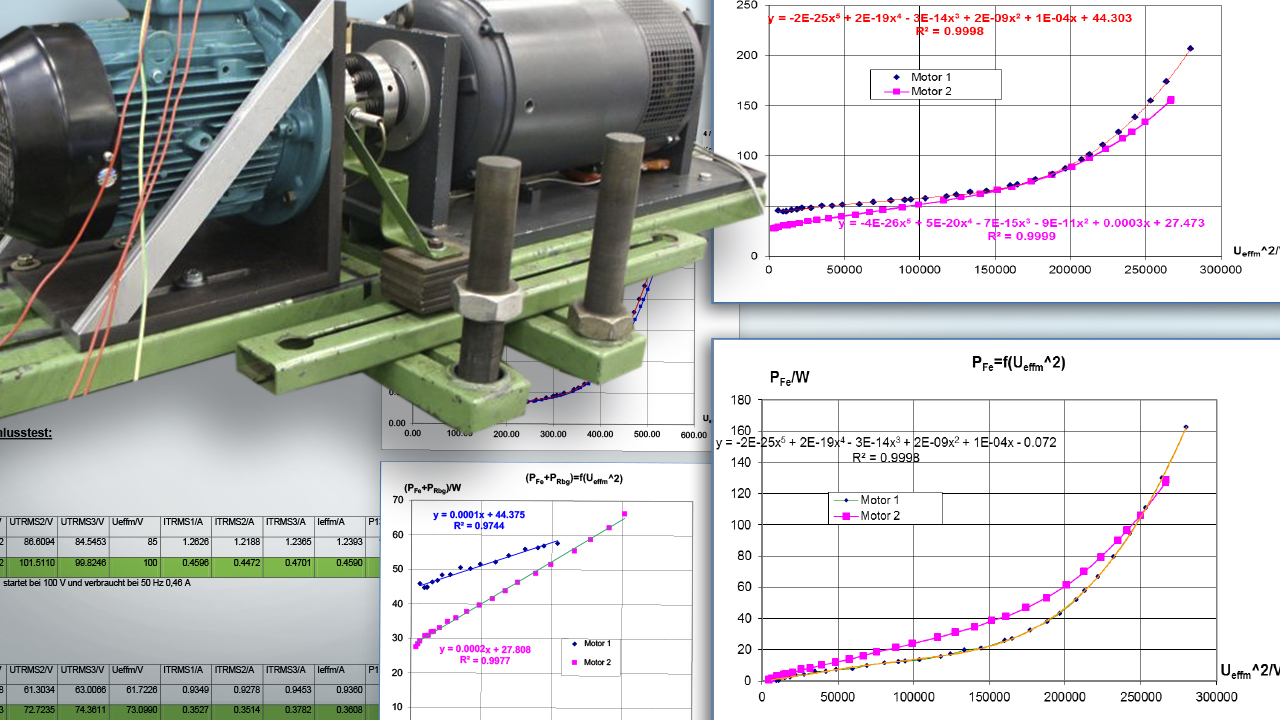

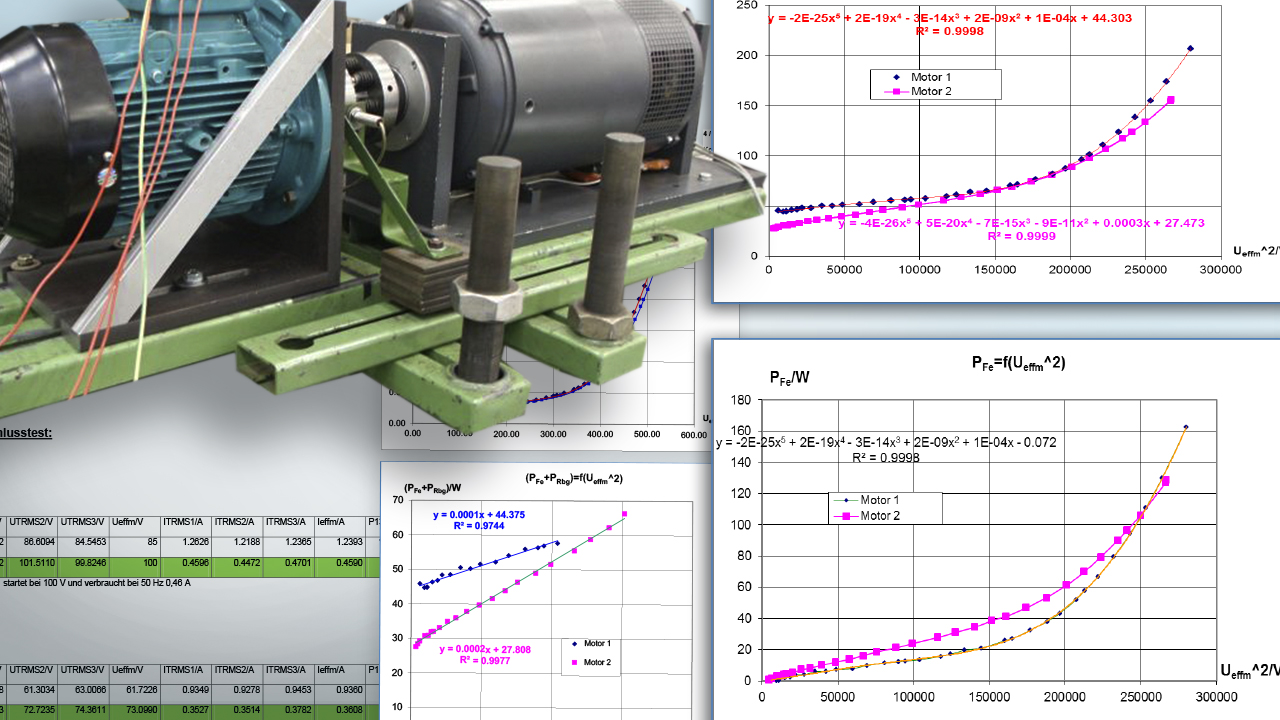

University Düsseldorf, 2016

Testing the Siemens motor modernized by applying the "Slavyanka" technology. University Düsseldorf, January 2016

The test was conducted in a Düsseldorf laboratory and was commissioned by the Saint Petersburg company "SPBEK"

The goal of the tests was to see how the "Slavyanka" winding would impact the performance of a motor produced by a well-known company. Siemens electric motors were chosen for rewinding: the original motor and the one rewound using the combined winding technology.

During the tests, the second motor demonstrated higher efficiency throughout the whole range. The test proved that even motors with initially good efficiency could be improved by replacing a regular winding with the combined one.

The test reports can be found here https://drive.google.com/file/d/1qBVDfIh_8Ehh2H65T8SLchvhZOW44OFC/view

Practical application of the "Slavyanka" technology

-

KAMAZ with the modernized generator

KAMAZ with the modernized generator

In summer 2017, the generator of "KAMAZ" from the "KAMAZ-Master" sports team was rewound using the "Slavyanka" technology. The rewinding made it possible to increase the generator power almost by 30%.

The modernized "KAMAZ" with Anton Shibalov's team took part in the 2017 Dakar Rally in South America with the route running through Paraguay - Bolivia - Argentina.

The "KAMAZ-Master" team was happy with the improvement, later the generators of the other cars were rewound for the 2018 Dakar Rally!

Besides, it was decided to apply the "Slavyanka" technology for the windscreen wipers motor of the racer KAMAZ cars.

The "KAMAZ-Master" generators were modernized by the company OOO "Electrocomplex", the licensee of OOO "ASiPP".

-

"ZAZ" electric car

Electric car ZAZ-966 with Duyunov's motor

Zaporozhets 汽車搭載使用到「Slavyanka」這項技術的現代化馬達,特別是 2015 年在基輔 - 蒙地卡羅舉辦的電動車馬拉松。

In Odessa, the founders of the "Ecofactor" project fully modernized the car within 3 weeks by changing the internal parts and leaving only the bodyshell intact.

In the race, the Odessan team crossed 10 countries and covered the distance of almost 3000 kilometres. At one of the route legs, ZAZ managed to overtake the Tesla electric car. There were no troubles with the electric car on the route, except for some minor loose ends that were quickly eliminated.

Zaporozhets was the fifth overall to arrive to the finish line and the second among the modernized electric cars. The Odessan electric car also won the people's choice award. Besides, the founder of the race, prince of Monaco Albert, paid attention to ZAZ, noting a very authentic exterior of the Ukrainian car.

Promo video about modernizing ZAZ — https://www.youtube.com/watch?v=m8uGFK2H-H8&t=40s

-

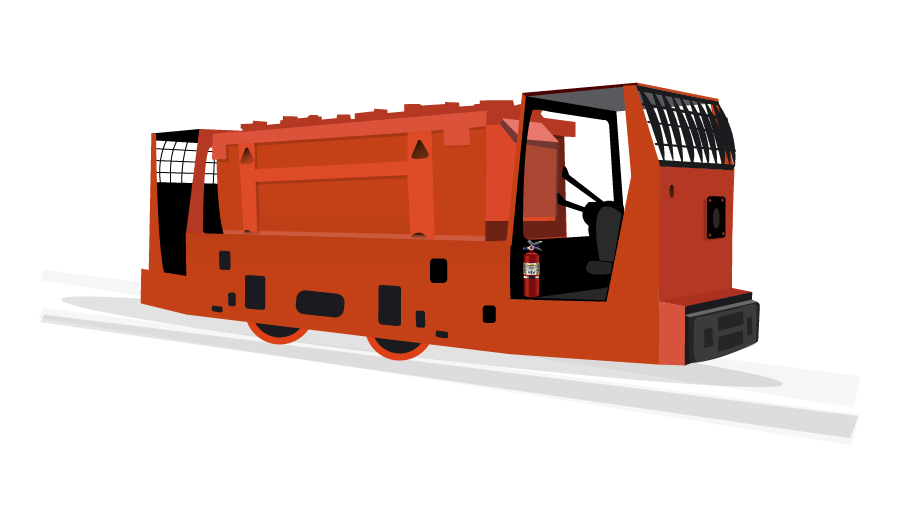

Mining electric locomotive "Era"

Mining electric locomotive Era

Electric locomotive Era is a vehicle used for freight transportation in the mines on a narrow-gauge railway.

In 2013, in Donetsk Era was equipped with a size-112 motor modernized using the "Slavyanka" technology instead of the original factory-supplied DRT-13, as well as a Сurtis controller.

The running tests demonstrated the following performance of the mining electric locomotive: it pulled 11 cars with coal while the previous one pulled 5, the speed was 12 km/h on a flat level surface and 7 km/h uphill, when transporting 100 tons of coal, the motor didn't overheat, despite the load increased two times.

Duyunov's development increased labour productivity of Donetsk miners twice alongside a considerable decrease in power consumption. The specialists also noted considerable reduction of high-frequency harmonics and reactive component in mains electricity that powered the traction step-down substations.

-

"Tavria" with Duyunov's motor

Tavria with Duyunov's motor

In 2014, the citizen of Belgorod region Igor Korkhov modernized the general purpose industrial motor in size 100 by rewinding it using the "Slavyanka" technology. As a result, the motor became 10 times more powerful with a comparatively light weight of 29 kilograms.

Before modernization, the motor power was 4 kW, and after - increased up to 12-13 kW, with the maximum of 50 kW.

"Igor Korkhov equipped the Tavria car with a modernized motor. The heavy car started quite vigorously in both first and third gear, while running very quietly. The maximum speed of the car amounted to 110 km/h, and it could run about 100 kilometres on a single charge ."

Igor Korkhov started modernizing Tavria back in the beginning of 2000s. The car had already been equipped with an electric motor, but the engineer wasn't satisfied with the speed that didn't exceed 50 km/h. So, he first equipped Tavria with an American commutator electric motor, and then - with a combined winding motor completed with a Curtis controller.

Tavria 至今仍在運作中,早已有了新主人。Igor Korkhov 已成為 Duyunov 團隊成員,目前在綠城行政區「 Sovelmash」工作。

Video about Tavria on Life News - https://www.youtube.com/watch?v=RhPMZyUspeI

-

Trolleybus in Kiev

Trolleybus in Kiev

In 2014, in Kiev at the premises of "KyivPasTrans", a trolleybus with a motor modernized using the "Slavyanka" technology was tested.

The modified drive increased the trolleybus speed and reduced power consumption. The project was terminated due to the unfavourable events in Ukraine.

-

Citroёn with Duyunov's motor

Citroёn with Duyunov's motor

In 2017, Dmitriy Duyunov's partner, Victor Arestov, in Germany installed a motor rewound using the "Slavyanka" technology in an old Citroën electric car.

The modernized electric car impressed the audience with fast start from rest, fast run and maneuverability. The car charge is enough for one hour.

Citroën performance after modernizing the motor:

Weight — 750 kg

Battery — 14 kWh

Controller Curtis 1238 96 V

Average charge consumption — 9.6 kWh per 100 km

Consumption in urban areas — 7.2 kWh per 100 km

Single charge range — up to 180 km

Maximum speed — 130 km/hModernizing the electric motor by applying the "Slavyanka" technology for Citroën resulted in considerable enhancement of the key performance features.

Video from Victor Arestov engaged in modernizing the electric car https://www.youtube.com/watch?v=RDdM2bclpKg&t=5s

One of the reports about Citroën in German https://www.youtube.com/watch?v=WtVqu0rLADw

-

Denzel Pickman truck

Denzel Pickman truck

Pickman electric car is a vehicle with a payload capacity of up to 500 kg. It is used for short-distance trips over small areas: in farming, tourism or production.

In September 2017, the truck was equipped with an electric motor modernized using the "Slavyanka" technology, smaller in size and weight than the standard operating motor. Thanks to the new motor:

the vehicle speed increased; the battery cycle increased.

Later on, Denzel Pickman was equipped with more powerful combined winding motors, modernized by ASPP Weihai using the "Slavyanka" technology.

In 2018 the truck was tested with a DA-90S motor.

In 2019 — with a DA-100S motor and a new lithium battery (84 Ah) instead of a lead one (100 Ah). The electric car demonstrated the following performance with them:

speed — 65 km/h, distance-to-empty — 100 km at an average speed of about 50 km/h.

Video of the Pickman tests — https://www.youtube.com/watch?v=dLcZMtuVOjI&t=9s

-

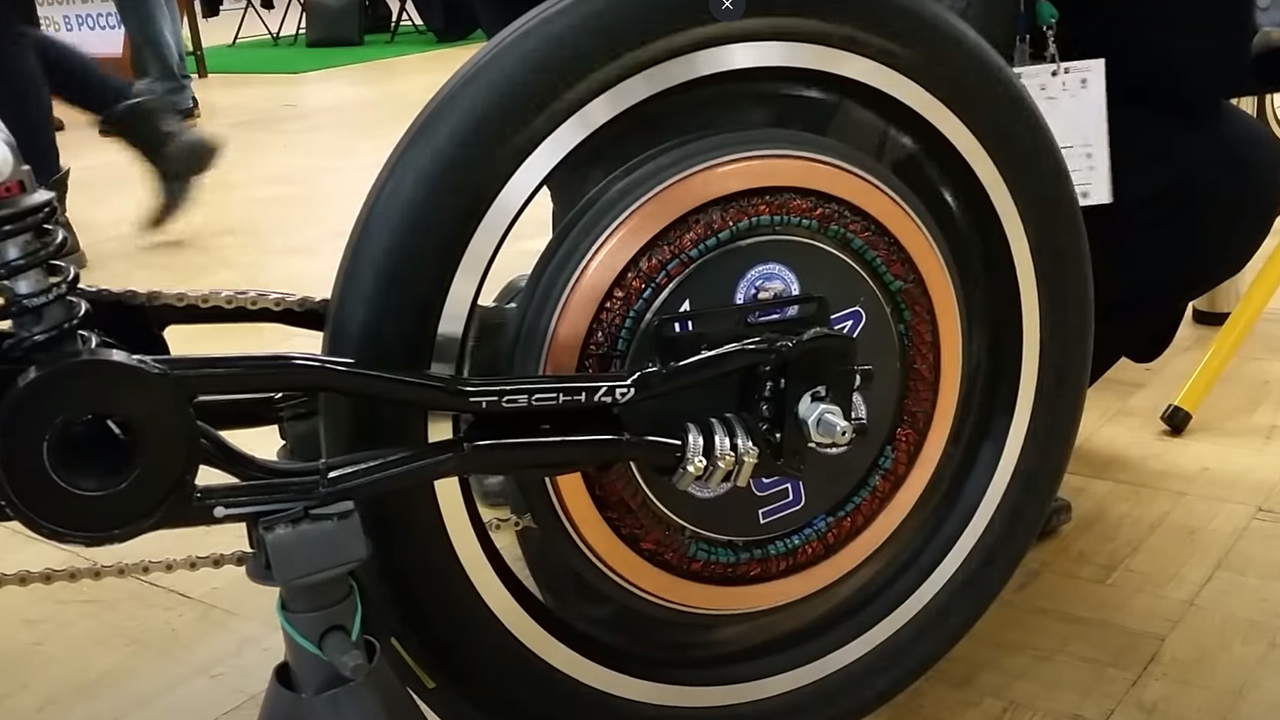

Electric scooter Irbis Grace with size-318 hub motor

Electric scooter Irbis Grace with size-318 hub motor

The Irbis scooter was modernized in 2016. The vehicle was equipped with one of the first prototype models developed by Duyunov, a 318-size hub motor. Besides, the rear float lever was replaced, and the steering system was supplied with a lever for regenerative braking. All the original factory-supplied electrics and control systems of the electric scooter remained intact.

The first test rides demonstrated better maneuverability of Irbis, it started easier and developed excellent speed. During a country road test ride, the scooter managed to develop the speed of up to 70 km/h.

Climax of the tests: Irbis Grace moved Niva (1500 kg) from rest and dragged it, thus demonstrating its power and endurance.

The video of Evgeniy Duyunov talking about the Irbis Grace scooter with size-318 hub motor - https://www.youtube.com/watch?v=WH3vAeIRElE&t=39s

-

Electric car Renault Kangoo

Electric car Renault Kangoo

In 2015, the member of Duyunov's team Victor Arestov applied the "Slavyanka" technology to rewind the motor of Renault Kangoo the electric motor of which had been prone to overheating. As a result, the motor stopped heating and the electric car distance range increased by 20%.

Later, an even more enhanced version of Renault Kangoo participated in 7 exhibitions in Monaco and in the south of France having amazed the visitors and specialists by: accelerating from rest in third or forth gear and a mountain trip in forth gear.

Renault E-Kangoo performance:

Car weight: 1560 kg

Controller: Curtis 1238-7601 650 A

Batteries: 33 x WINSTON WB-LYP200AHA 3.2 V (33 x 3.2 V x 200 AHA = 21.120 kWH)

"Slavyanka" motor: size 112, weight 60 kg

Power: max 57 kW (controller restricted); nominal: 35 kW

Motor revolutions: up to 9000 (Curtis controller restricted up to 8000 rev/min)

Maximum speed: up to 150 km/h

Maximum distance range: up to 210 km at 50 km/h

Consumption at 50 km/h: 5.7-6.2 kWh; at 80 km/h: 12.7 kW (four-wheel drive 4x4)

Acceleration time 0-100 km/h: 14 sec.The electric car has been in running order up to the present day outperforming the Renault and Citroёn cars of the same type.

Renault Kangoo in action - https://www.youtube.com/watch?v=6bgLduo-xWs&t=1s

-

Electric car Renault Twizy

Electric car Renault Twizy

The original motor of Renault Twizy electric car was rewound using the "Slavyanka" technology in 2017 in Germany.

Testing Twizy started with an outdated 5-year battery that, however, didn't become an obstacle for enhancing the vehicle performance.

After modernization, the electric car could boast the following performance enhancements:

- distance range increased by over 20 %,

- motor power increased up to 18 kW,

- the motor didn't overheat remaining slightly warm.The electric car was presented at the EVER and Top Mark exhibitions in Monaco in April 2017. The audience were amazed by its free maneuvering in the traffic and distance range.

直到今日,Twizy 仍被保留在俄國矽谷綠城行政區「Sovelmash」境內,等待進一步改良規格。預計會加裝新的電池到電動車上方,電池僅有 60 公斤重(有別於傳統 120 公斤重的磷酸鐵鋰電池),卻能和先前的電動車保有一樣強大的馬力。

-

Electric car Zetta

Electric car Zetta

One of the high-profile developments with Duyunov's hub motor was Zetta.

Zetta (back then - El-Panda) was first introduced in September 2017 at an exhibition in Ulyanovsk where it was noted by the President of Russia.

Size-318 hub motors were used in the electric car design with the maximum power of up to 18.1 kW, the torque of about 200 Nm. I.e., in total the hub motors develop the power of 72.4 kW (98 hp) and the torque of 800 Nm.

Every motor has its own controller, therefore the electric car can go both in four-wheel drive mode and in front-wheel or rear-wheel drive mode. The controllers are torque-synchronized together, which contributes to the travel quality.

Li-ion batteries of Zetta have the capacity of 10 kW*h, provide power enough for 200 km without recharging, meanwhile, the consumption is 40 W*h per kilometre.

The frame design is universal, which means that it can be applied for different kinds of bodyshells.

Evgeniy Duyunov's interview about Zetta - https://www.youtube.com/watch?v=z0RYgIYIzOc&t=1s

Presentation of Zetta - https://www.youtube.com/watch?v=V8GnFw87bAk&t=5s

-

Size-186 hub motor

Size-186 hub motor

The world's first induction hub motor is one of the most popular developments of Dmitriy Duyunov's team. This is a motor installed in the wheel of an electric vehicle, be it a bicycle, scooter, motorcycle or car. Duyunov's hub motor employs the combined winding technology "Slavyanka".

The analogues of Duyunov's hub motor are BLDC motors with magnets. To produce them, the rare-earth metals are needed that only China can provide in the required amount. Taking into consideration the progressively growing popularity of electric transport worldwide, the induction hub motor is not simply an analogue, but a fully functional, more effective and affordable substitute to the Chinese BLDC motors.

Work on size-186 hub motor ("Kolobok") started on February 4, 2015. Initially, it was designed for a wheelchair scooter: a piece of equipment that provides more mobile transportation for disabled people. Later, size-186 "Kolobok" was tested on a bicycle.

The hub motor doesn't overheat, withstands external impact, is resistant to water, dust and dirt, vehicles equipped with it demonstrate high speed.

Motor performance:

weight — 8 kg, <br>maximum efficiency — 94 %, <br> maximum speed of the bicycle with the hub motor — 101 km/h, <br>starting torque at the start - 52 Nm, <br>torque — 200 Nm <br>maximum torque — 76 Nm. <br>maximum power — 20 kW,

Duyunov's hub motor is distinguished by durability and long service life, its production cost is 30% lower, it's also cheaper to maintain. Vehicles with the hub motor demonstrate increased travel distance.

Later, a size 318 hub motor was designed weighing 18 kg. Sizes 186 and 318 are the minimum and maximum ones, Duyunov's team are working on the intermediate size. Over the course of testing and running, the hub motors have been tested on various bicycles: "Gran", "Versiya", El Moto, Denzel Sparta, Denzel Escort

-

Angle grinder

Angle grinder

「Sovelmash」工程師使用到感應短路驅動器,應用到結合繞線技術,將這台 UShM 230/2100M 角磨機改成現代化設計。

那麼「Sovelmash」實驗室會針對標準、改良機器,執行比較性能測試。測試發現角磨機使用到 Duyunov 馬達,運作會更為順暢:旋轉明顯、噪音級和切割品質良好。

Besides, the following peculiarities have been noted:

- the no-load speed of the classic angle grinding unit is higher than of the induction drive angle grinder, but under the load, the difference between them gets completely eliminated; - the "Slavyanka" model has much fewer constituent parts which leads to faster cutting and increasing service life of the angle grinder; - weight and noise level of the induction drive angle grinder are lower than the rival's.

Enhanced performance of the "Slavyanka" angle grinder improves productivity and comfort level of operating it.

Dmitriy Duyunov about developing a specialized induction drive designed for power tools - https://youtu.be/ltLRWSdZBIo

View the comparative tests of the angle grinder with "Slavyanka" and classic angle grinder here - https://youtu.be/oiavBAL9OXo

Small-scale production

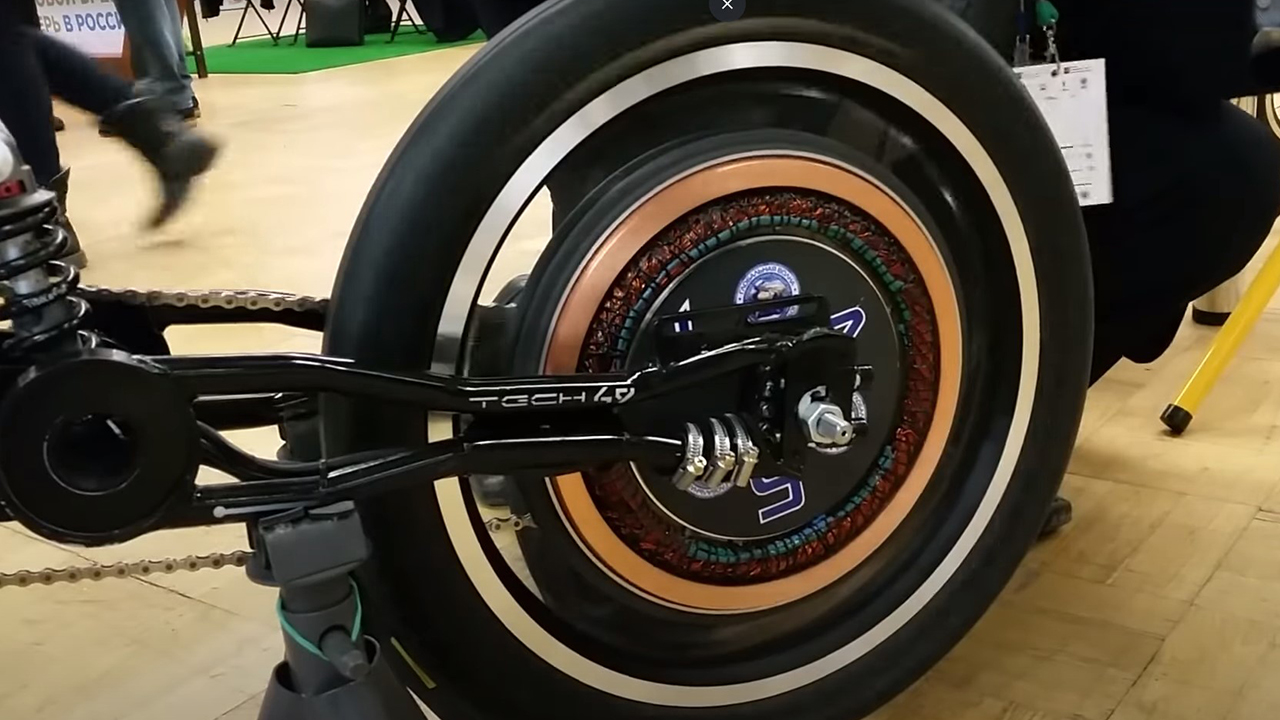

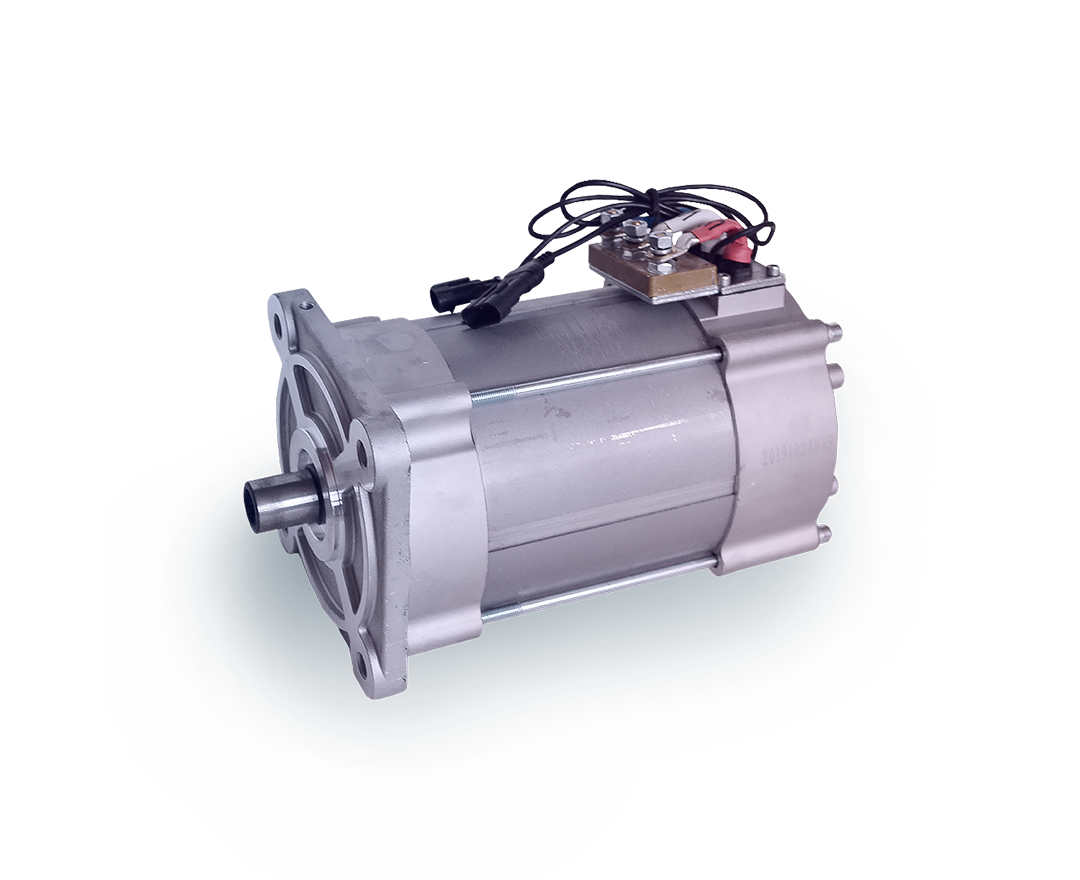

DA-90S electric motor

Induction motor produced in China and modified using the "Slavyanka" technology

- Motor type: induction motor

- Nominal power: 3 kW (3300 rev/min)

- Peak power: 9.5 kW

- Continuous current (maximum value): 60 A (phase current)

- Peak current: 350 A

- Nominal voltage: 72 V

- Maximum speed: 5000 rev/min

- Efficiency: 92 %

- Torque (maximum value): 74 Nm (on the shaft)

- Weight: 10.5 kg

- No magnetic resistance

- Improving efficiency within the whole load range

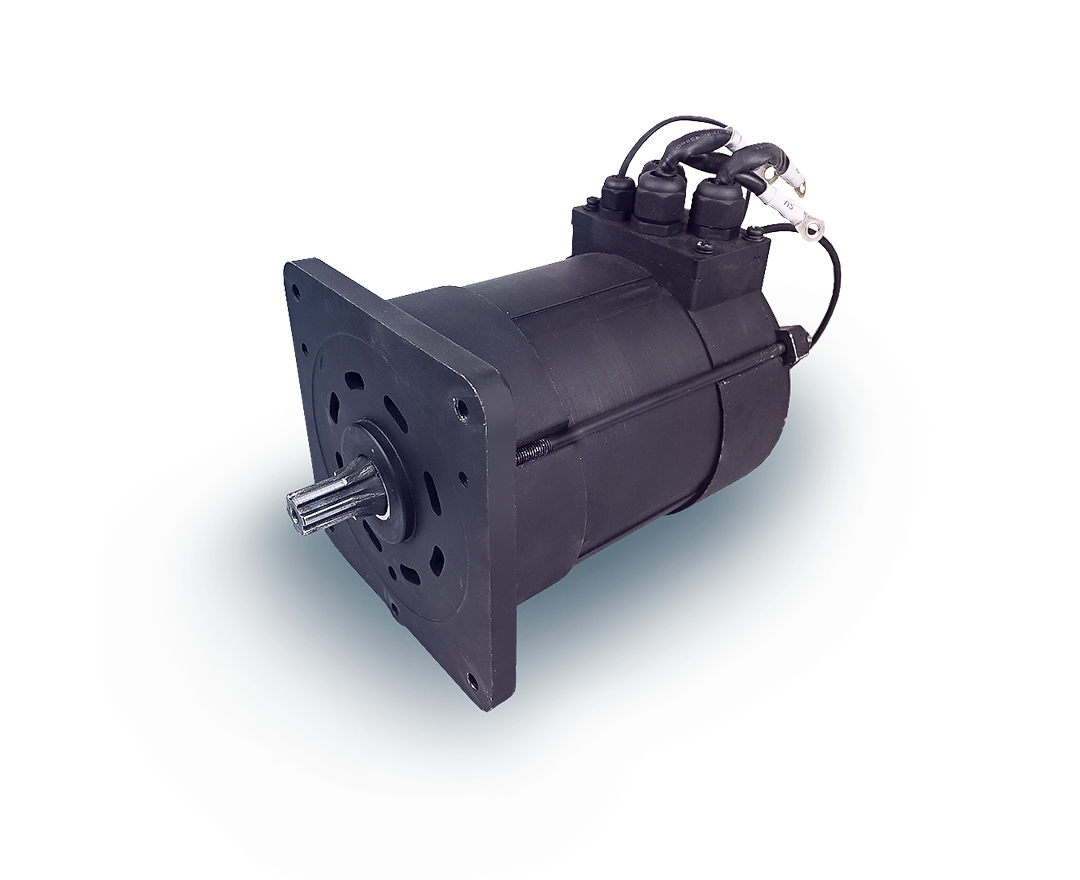

DA-90SM 電動馬達

Induction motor produced in China and modified using the "Slavyanka" technology

- Motor type: induction motor

- 額定功率:4 kW (3300 rpm)

- 最大功率:10 kW

- 長期電流(最大值):80 A(相電流)

- Peak current: 350 A

- Nominal voltage: 72 V

- Maximum speed: 7000 rev/min

- Efficiency: 92 %

- Torque (maximum value): 74 Nm (on the shaft)

- 重量:11.2 kg

DA-95S 電動馬達

Induction motor produced in China and modified using the "Slavyanka" technology

- Motor type: induction motor

- 額定功率:5 kW (3300 rpm)

- Peak power: 14.5 kW

- 275 A 的力矩為 83.3 Nm

- 長期電流(最大值):80 A(相電流)

- Peak current: 350 A

- Nominal voltage: 72 V

- Maximum speed: 7000 rev/min

- 效率:95 %

- 力矩(最大值):106 Nm(軸上)

- 重量:14 kg

DA-112S 電動馬達

Induction motor produced in China and modified using the "Slavyanka" technology

- Motor type: induction motor

- Nominal power: 7 kW (3200 rev/min)

- Peak power: 21 kW

- 定電流:120 A(相電流)

- 峰值電流:550 A

- Nominal voltage: 72 V

- 最大速度:7500 rpm

- Efficiency: 91 %

- 力矩(最大值):151 Nm(軸上)

- 重量:23 kg

DA-112SL electric motor

Induction motor produced in China and modified using the "Slavyanka" technology

- Motor type: induction motor

- Nominal power: 12 kW (3200 rev/min)

- Peak power: 36 kW

- Continuous current: 260 A (phase current)

- Peak current: 650 A

- Nominal voltage: 72 V

- Maximum speed: 7000 rev/min

- Efficiency: 93 %

- Torque (maximum value): 210 Nm (on the shaft)

- Weight: 35 kg

- No magnetic resistance

- Improving efficiency within the whole load range

SPECIFICATION scooter with DA-90S electric motor

Denzel Liberty 電動機車撘載 DA-95S 馬達

SUZUKI AX-100 electric motorcycle with DA-90S electric motor

咖啡賽車手的電動機車撘載 DA-95S 馬達