Kombinirana navitja "Slavyanka"

O tehnologiji kombiniranih navitij "Slavyanka"

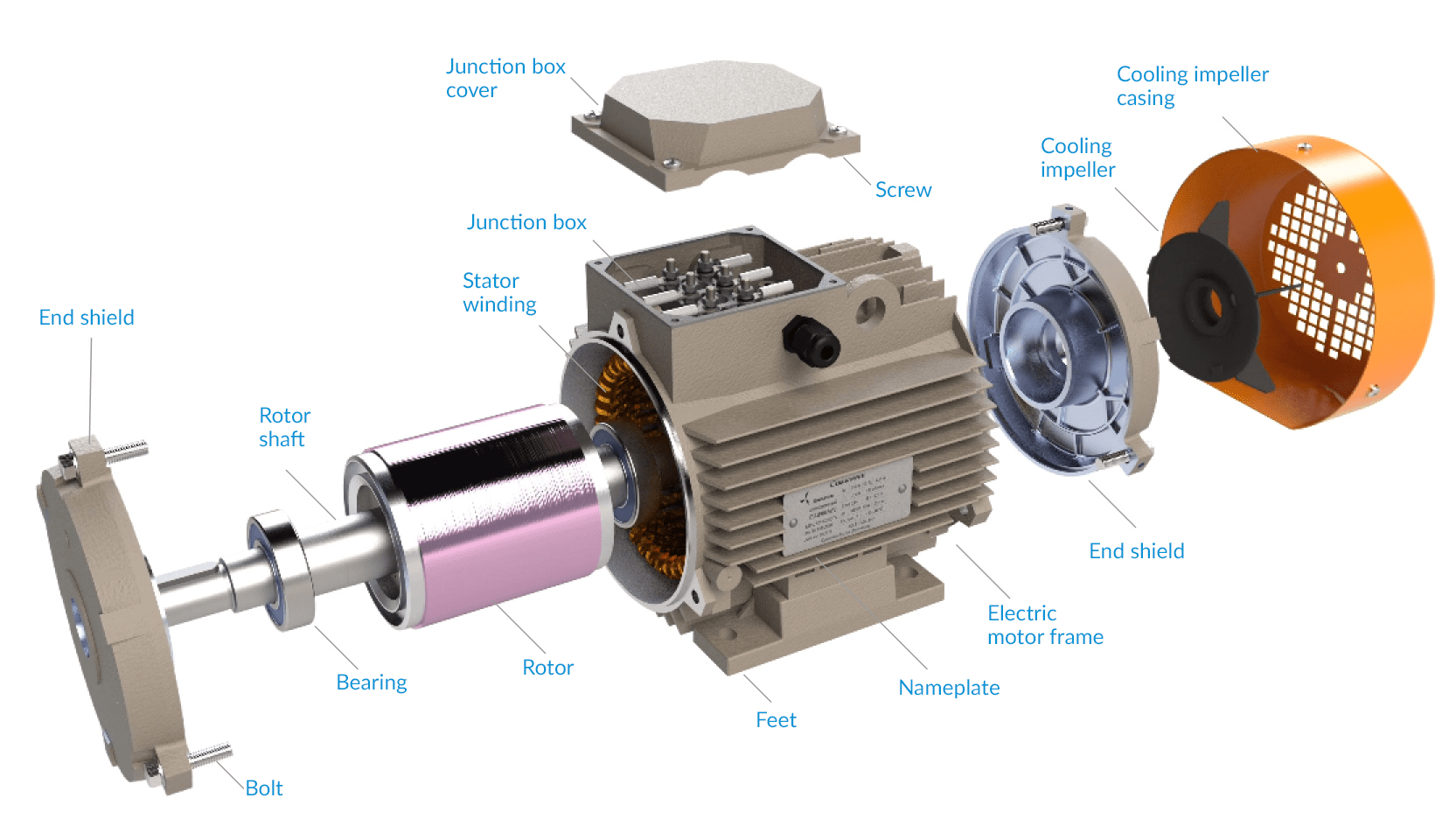

Tehnologija kombiniranih navitij "Slavyanka" se uporablja za večino tipov in vrst električnih rotacijskih enofaznih in trifaznih strojev. Takšni motorji imajo vgrajeno navitje, ki je v klasični različici povezano bodisi v "zvezdo" bodisi v "trikotnik".

Posebnost "Slavyanke" je, da sta v enem elektromotorju združeni dve vrsti navitij. "Zvezda" in "trikotnik" sta povezana vzporedno s premikom nastalih vektorjev elektromagnetne indukcije pri 30 električnih stopinjah.

Kombinirana navitja so dobila ime "Slavyanka". Motorji z njimi imajo edinstvene značilnosti in presegajo vse svetovne analoge, ki obstajajo na trgu.

Več informacij o tehnologiji najdete na spletni strani "Sovelmash".

Prednosti elektromotorjev s "Slavyanko"

Povečan razred energetske učinkovitosti

Področja uporabe

-

Электровелосипеды

-

Električni mopedi

-

Električna motorna kolesa

-

Električni avtomobili

-

Javni prevoz

-

Электролокомотивы

-

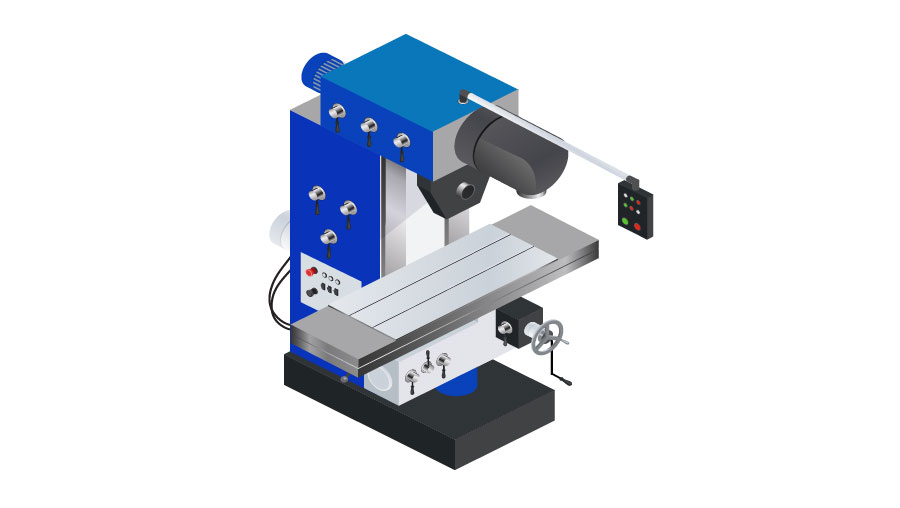

Obdelovalni stroji

-

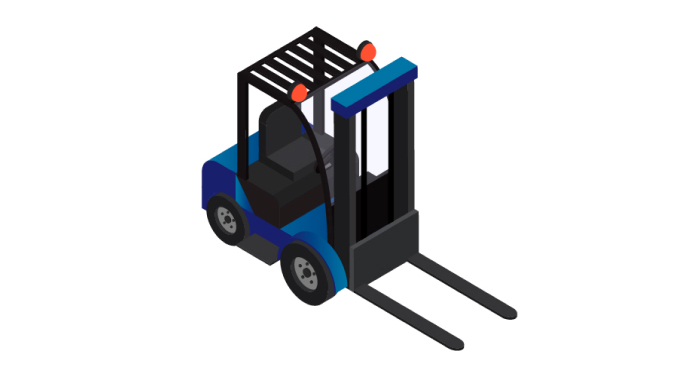

Dvižna oprema

-

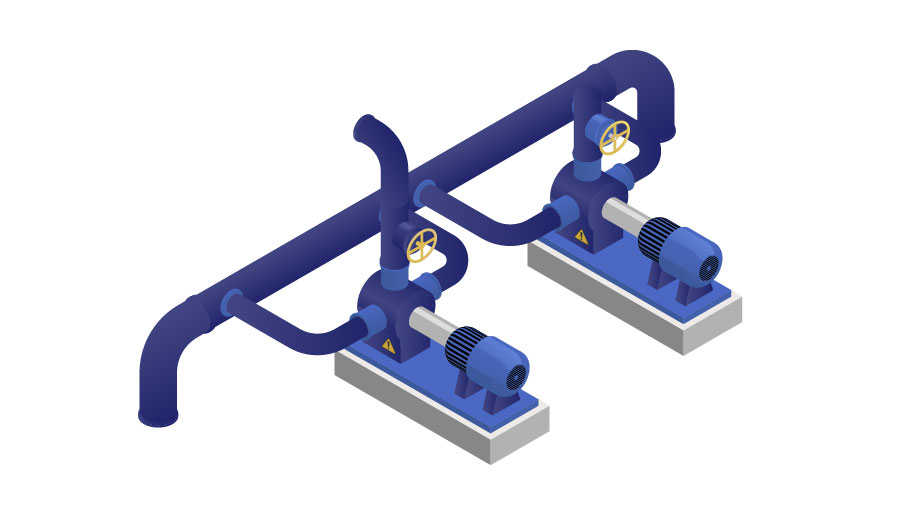

Насосы

-

Prezračevanje

-

Oprema za žerjave

-

Transportne linije

-

Vetrni generatorji

-

Hidroelektrarne

-

Termoelektrarne

-

Jedrske elektrarne

-

Mobilne proizvodne naprave

-

Obnovljiva energija

-

Hladilniki

-

Pralni stroji

-

Sesalniki

-

Pomivalni stroj

-

Ventilatorji

-

Mikrovalovna pečica

-

Kmetijska oprema in stroji

-

Gradbena oprema in stroji

-

Medicinska oprema

-

Ladje, jahte, čolni

-

Vojaška oprema

-

Letalstvo

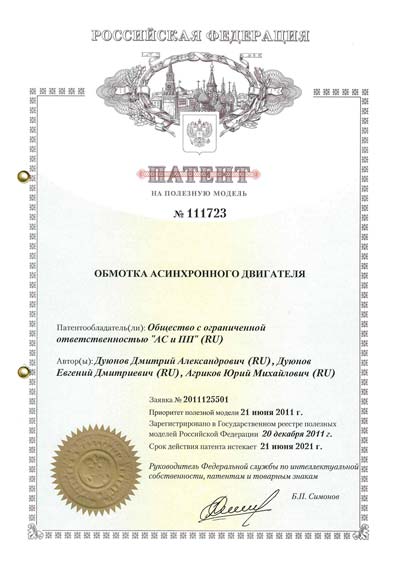

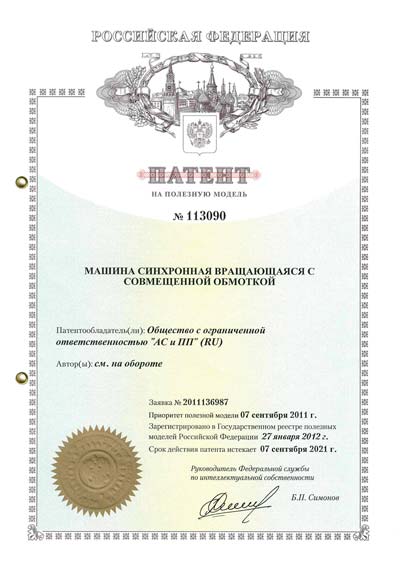

Patenti

Raziskave elektromotorjev s "Slavyanko"

-

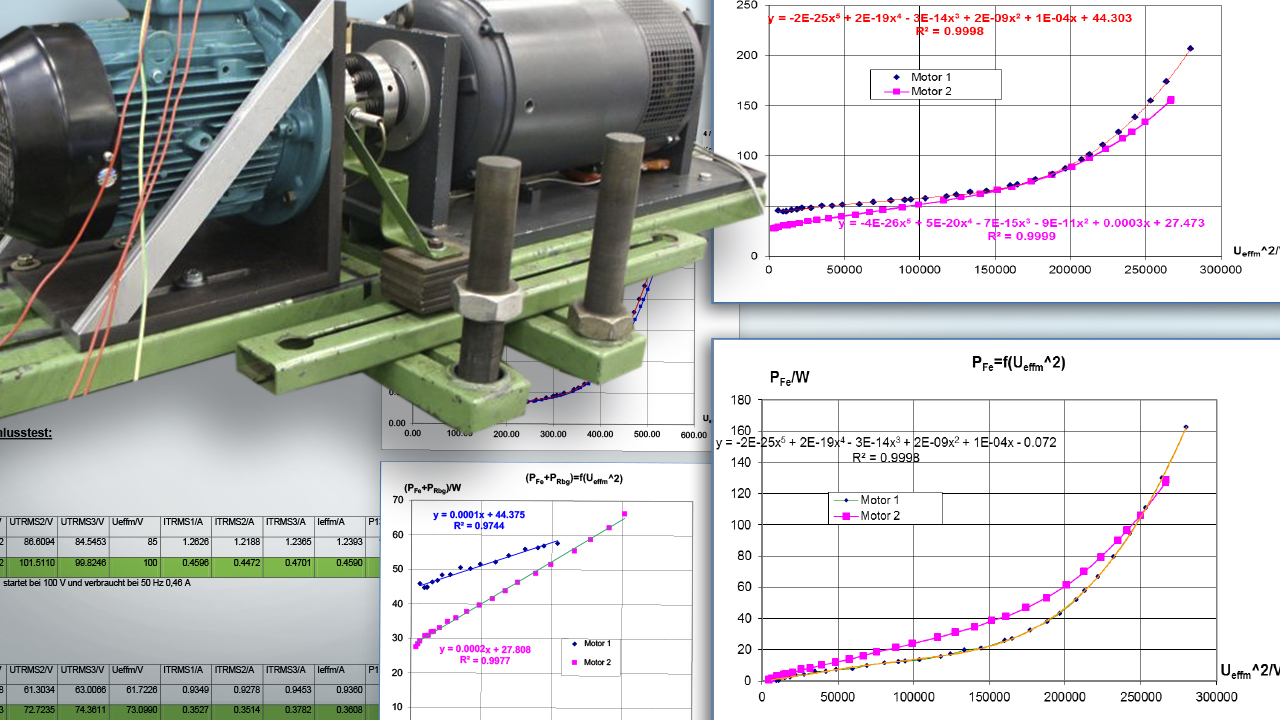

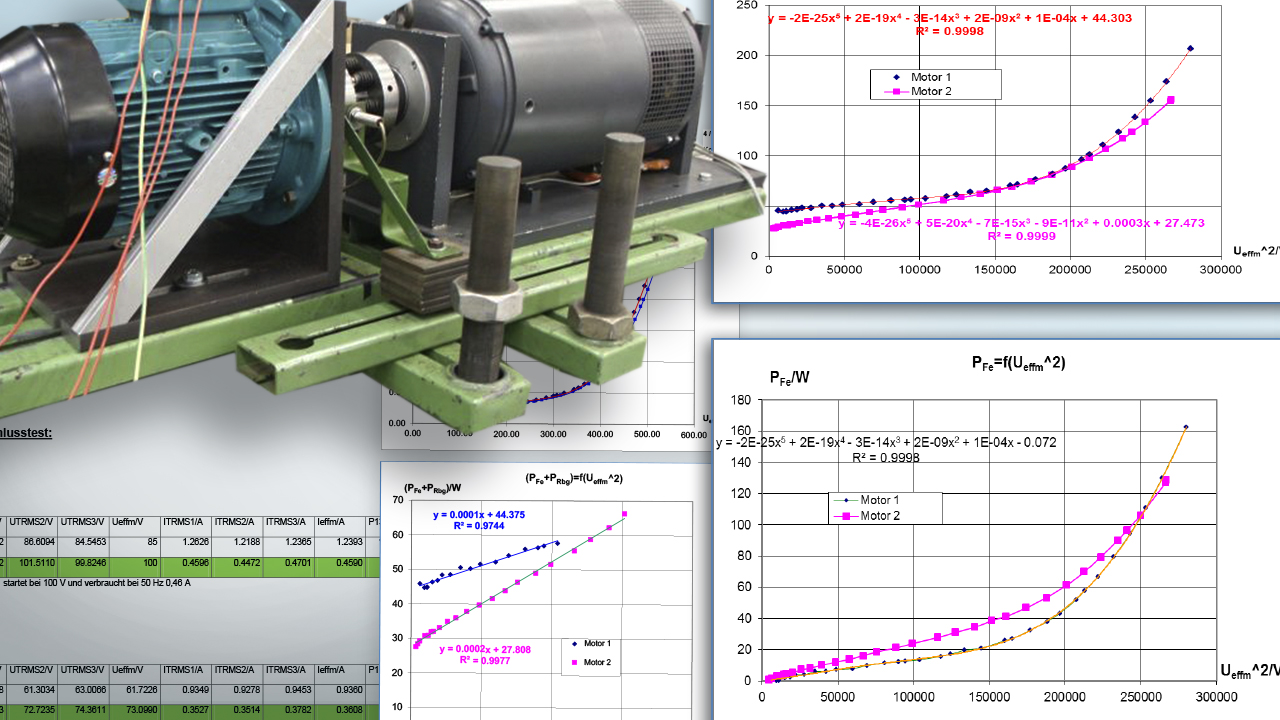

Univerza v Dusseldorfu, 2016

Primerjalni testi splošnega industrijskega motorja, previtega s tehnologijo "Slavyanka". Univerza v Dusseldorfu

Neodvisni testi splošnih industrijskih motorjev so bili opravljeni na podiplomski šoli Univerze v Dusseldorfu.

Naloga je bila preizkusiti originalni motor, nato pa ga previti na "Slavyanko", preizkusiti nadgrajeni motor in primerjati rezultate.

Za testiranje je bil na voljo 7,5 kW motor. Testi so pokazali, da po nadgradnji na Slavyanko: <br>- ima 30% višji moment, <br>- porabi do 30% manj električne energije.

Poročila o testih si lahko preberete tukaj - https://clck.ru/G7VX9

-

Univerza v Bologni, 2013

Primerjalni testi motorja, navitega na "Slavyanko". Univerza v Bologni, september 2013

Naloga testiranj je ustvariti motor s kombiniranimi navitji za električne vozičke na osnovi tehnologije "Slavyanka" in izvesti primerjalni test s standardnim motorjem.

Standardni motor, izdelan posebej za buggyja, je tehtal 54 kg in imel bakreni rotor. Za testiranje tehnologije "Slavyanka" je bil izbran splošni industrijski motor, težak 27 kg, z aluminijastim rotorjem.

Njegove tehnične značilnosti: 4-polni AEG motor dimenzije 100, 3 kW, 86-odstotni izkoristek in IE2 razred energijske učinkovitosti. Med testiranji je bil uporabljen krmilnik, razvit na univerzi, ki se je popolnoma zlil z motorjem, navitim s pomočjo tehnologije Duyunova.

Testiranje je potekalo v treh različnih načinih: • nominalnem 135 A, • 270 A, • 350 A.

Posledično modificirani motor ni dosegel 1 kW nazivne in 1 kW maksimalne moči. Prejšnji motor električnega vozička je proizvedel 20 kW moči pri 350 amperih, s kombiniranimi navitji pa 19 kW.

Razlike so bile tudi glede učinkovitosti: motor električnega vozička - 91%, spremenjeni splošno industrijski motor "na Slavyanki" - 89%.

Viktor Arestov, ki je vodil izvajanje testov, je priznal, da izbira motorja za testiranje ni bila povsem pravilna. Da bi dosegli načrtovane rezultate, je bilo treba izbrati tak motor dimenzije 112, ne pa 100, s 4 kW več moči.

Vendar je vredno razmisliti o tem, da je bila razlika v teži motorjev skoraj dvojna, posebni motor za električni voziček pa je imel bakreni rotor, medtem ko je modificirani motor imel aluminijast (če aluminijasti rotor spremenite v bakreni, lahko izkoristek povečate za 2-3%).

Pri tem pa je motor s kombiniranimi navitji, ki je težek 27 kg, pokazal skoraj enake parametre kot posebej razvit originalni motor s težo 54 kg!

S poročili testiranj se lahko seznanite tukaj - https://clck.ru/GQgTM

-

Univerza Belgorod, 2016

Primerjalni testi asinhronih elektromotorjev. Univerza Belgorod, 2016

Na Belgorodski državni tehnološki univerzi so izvedli primerjalne teste dveh asinhronih elektromotorjev AIR 71V4.

Namen dogodka je bil preveriti prijavljene značilnosti elektromotorja AIR 71V4, posodobljenega po tehnologiji "Slavyanka", s tovarniško izdelanim analogom, vendar s standardnim trifaznim navitjem.

Med testiranji so opazili zmanjšanje hrupa in temperature ogrevanja modificiranega motorja. Zabeležili smo znatno izboljšanje značilnosti posodobljenega elektromotorja v skoraj vseh načinih in povečanje učinkovitosti pri širšem obsegu obremenitev.

Ugotovljeno je bilo, da bo v procesu dejanskega delovanja motor s kombiniranimi navitji zmanjšal porabo električne energije za 14-20%. Najvišje ekonomične kazalnike lahko dosežemo v načinih delovanja električnega pogona z obremenitvijo motorja, ki je nižja od nazivne. Poleg tega bodo zmanjšanje zagonskega in nazivnega toka, zmanjšanje delovne temperature navitja statorja, zmanjšanje notranjih vibracij vodnikov v tuljavah in utorih statorja znatno zmanjšali stopnjo obrabe izolacije vodnika.

Raziskovalci priporočajo tehnologijo Slavyanka za popravilo asinhronih elektromotorjev v industrijskih obratih, z namenom, da bi znatno prihranili energijo.

Poročilo o testiranjih je na voljo na https://drive.google.com/file/d/1e6RKjKRkJq28NUDDz8i216c6ES_5HbIB/view

-

Kamnolom Beograd, 2015

Testiranje motorja s "Slavyanko". Beograd, 7. oktober 2015

Namen testiranja je ugotoviti, kako so se spremenile značilnosti elektromotorja po spremembi vrste navijanja iz tradicionalnega v kombinacijo "zvezda-trikotnik".

V srbsko podjetje D.O.O. "Savian" je za posodobitev bil posredovan asinhroni elektromotor z močjo 15 kW z izgorelim navitjem. Motor je deloval v kamnolomu. Lastnik motorja, D.O.O. Kuevo, je naročil popolno popravilo s spremembo vrste navijanja.

Zaradi uporabe varčne tehnologije "Slavyanka" so se tehnične karakteristike nadgrajenega motorja spremenile na sledeči način.

Nazivna moč se je povečala s 15 kW na 19 kW, tj. za 26,6%.

Tokovi prostega teka pred popravilom niso bili določeni, saj je bil motor okvarjen. Glede na dokumentacijo je ta vrednost znašala 27 A, po posodobitvi pa se je zmanjšala na 13,4 A.

Izvedeni testi so jasno pokazali energetsko učinkovitost tehnologije "Slavyanka". CTO D.O.O. Kuevo je potrdil zanesljivost nadgrajenega motorja.

Poročilo o preskusu najdete tukaj https://drive.google.com/drive/u/0/folders/1H5tQwSIQX9siP_J_-t9zf6bCMGaQ9Nq5?ths=true

-

Ruska tovarna, julij 2016

Testiranja posodobljenega motorja drenažne črpalke. Rusija, julij 2016

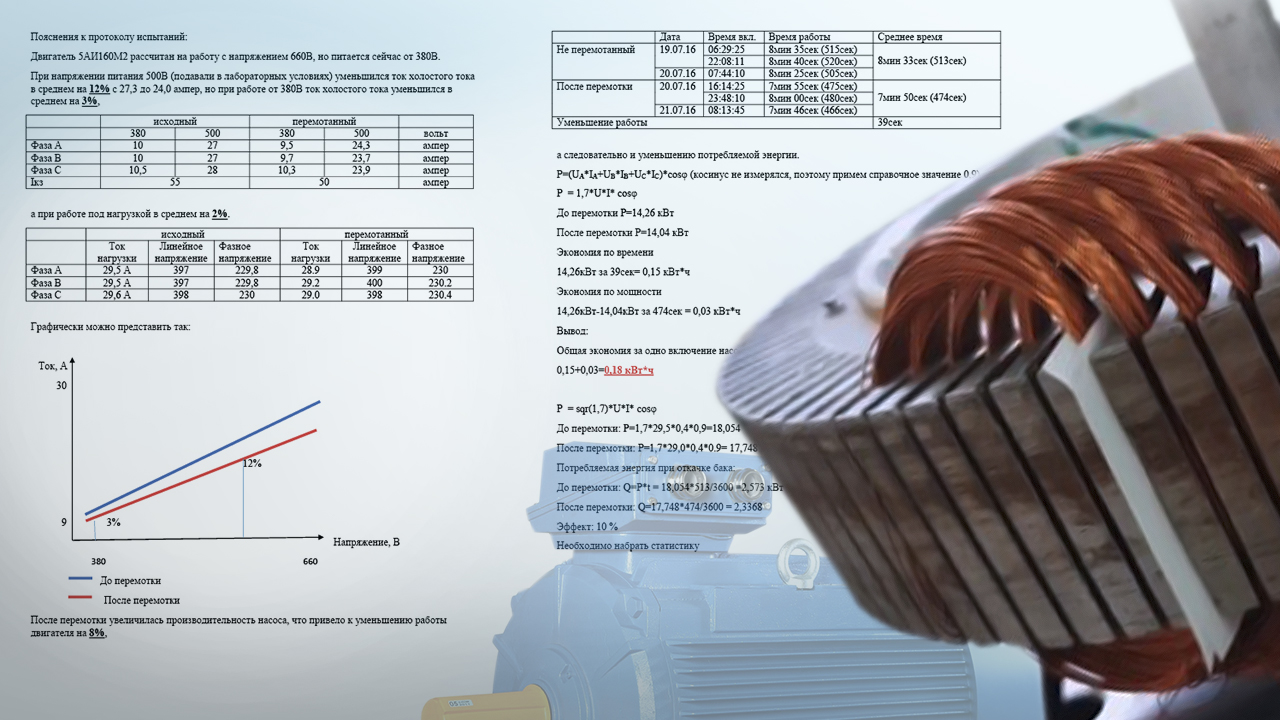

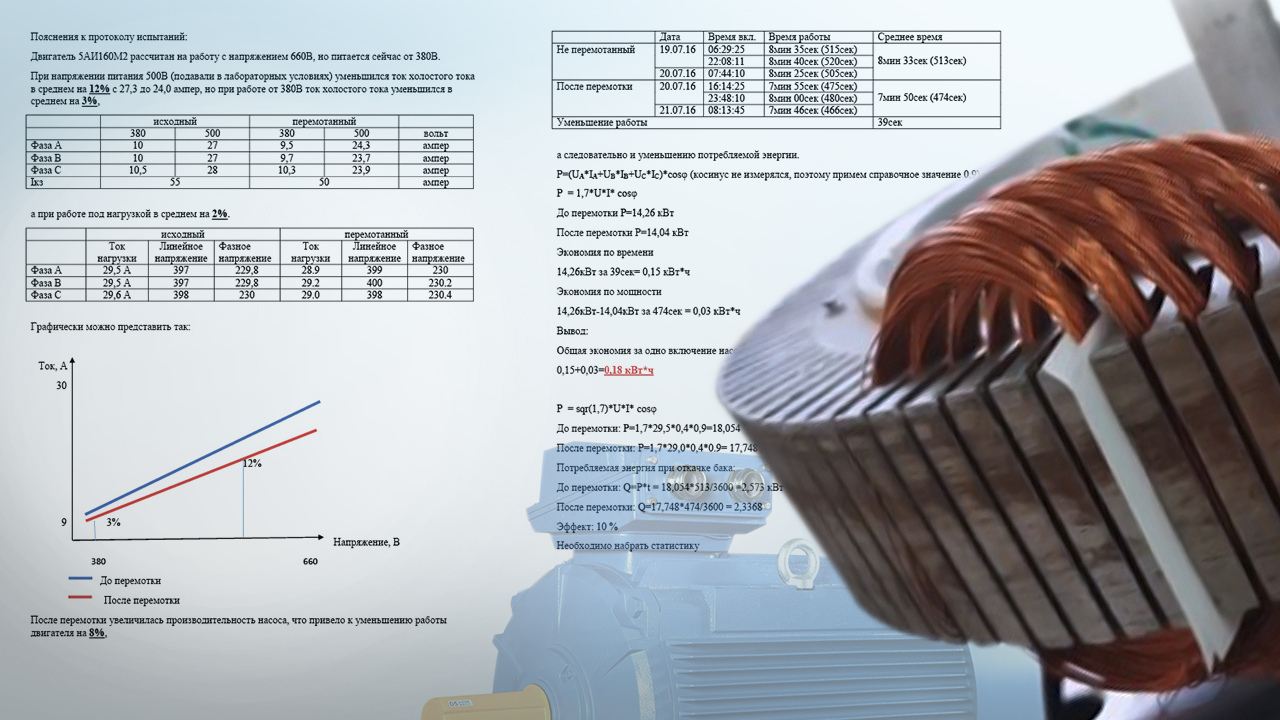

Inženirji ruske tovarne so samostojno izvedli posodobitev asinhronega elektromotorja 5AI160M2U2 z močjo 18,5 kW, nameščenega v odtočni črpalki. Med popravilom je bilo odstranjeno staro zgorelo navitje, motor pa je bil previti z uporabo patentirane tehnologije "Slavyanka".

Namen testiranja je ugotoviti spremembe tehničnih lastnosti motorja po njegovi posodobitvi.

Pred popravilom je bil električni motor 5AI160M2 zasnovan za delo z napetostjo 660V, po posodobitvi pa ga poganja 380V. Pri napetosti 500 V, ki se uporablja v laboratorijskih pogojih, se je tok v prostem teku zmanjšal v povprečju za 12% (s 27,3 A na 24,0 A). Pri obratovanju od 380 V se je tok v prostem teku zmanjšal za 3%, pri delovanju pod obremenitvijo pa za 2%.

Po previjanju se je zmogljivost črpalke povečala (čas cikla delovanja črpalke se je zmanjšal za 39 sekund). To je povzročilo zmanjšanje potrebnega časa delovanja motorja za 8%. Skupni prihranek energije za aktiviranje črpalke je bil 12%. Poraba energije pri črpanju rezervoarja pred previjanjem je dosegla 2,573 kW, po previjanju pa se je zmanjšala na 2,3668 kW. Prihranek - 10%.

Rezultati testov so potrdili učinkovitost kombinirane tehnologije navijanja "Slavyanka".

Poročila o preskusih in njihova pojasnila so na voljo na tej povezavi https://drive.google.com/drive/u/0/folders/1a1fglrN6zxjGJ1b7o3DLrUbMPJgn13PJ?ths=true

-

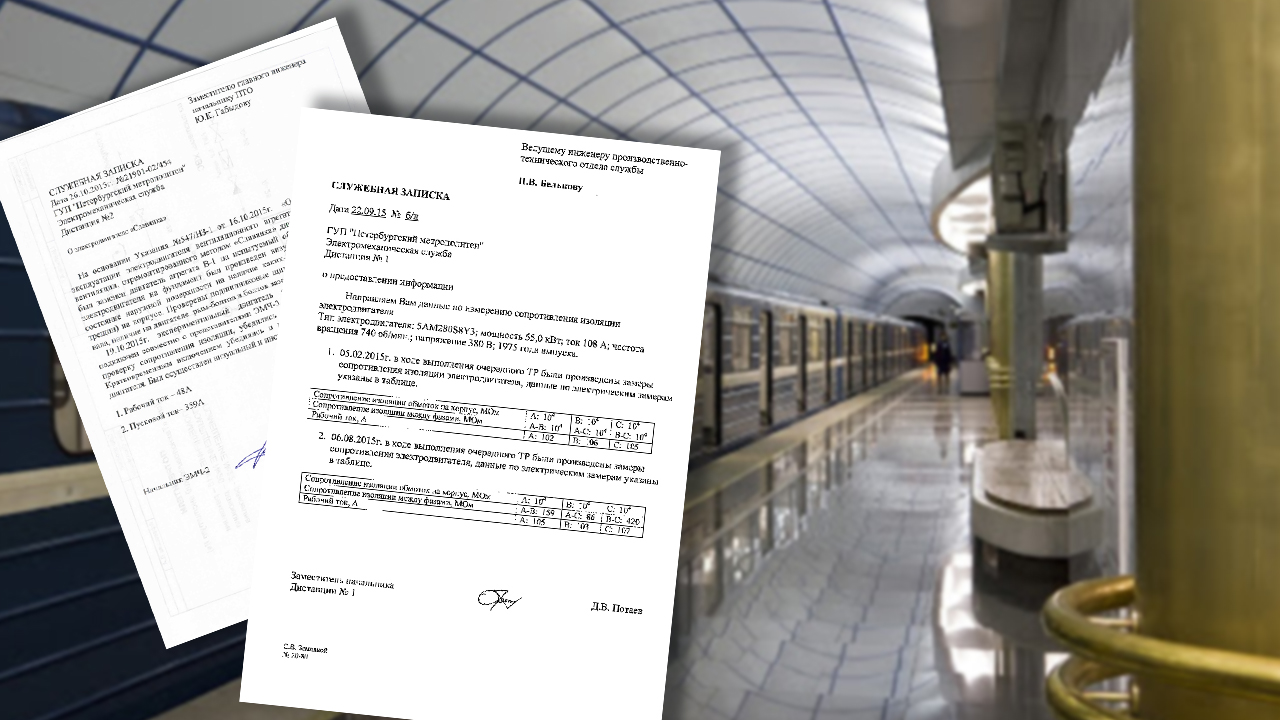

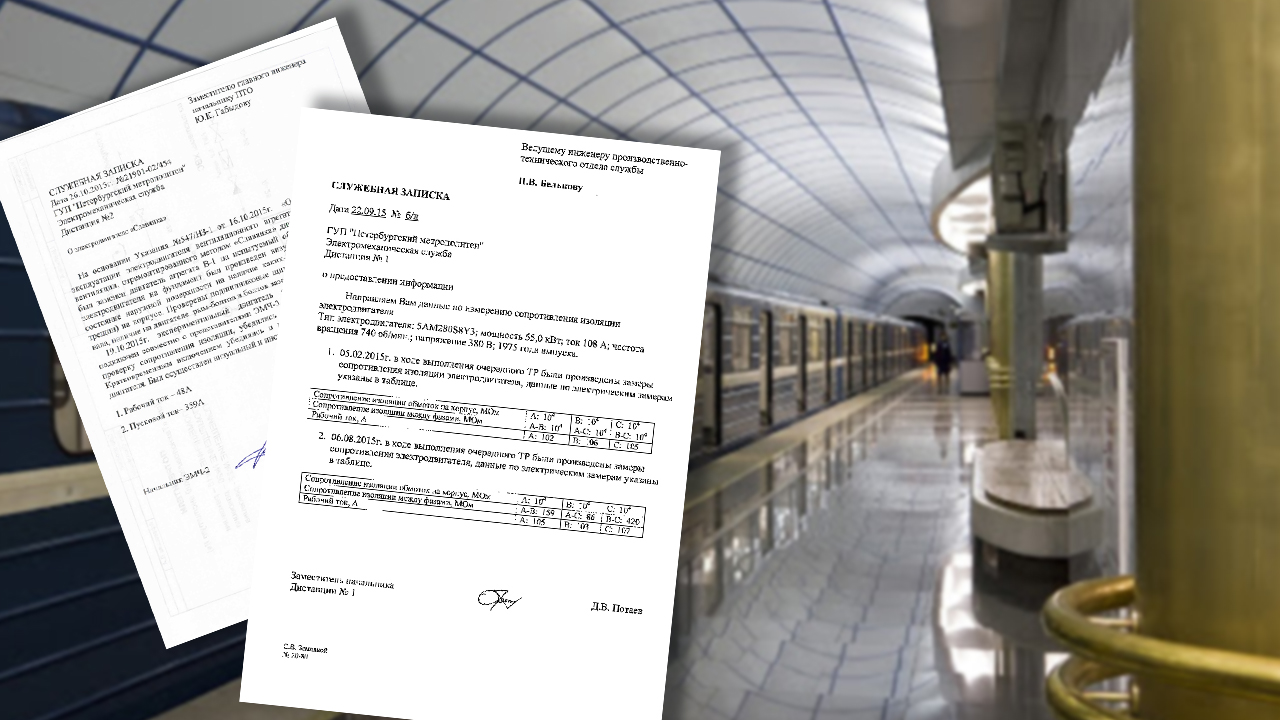

Metro v Sankt Peterburgu, 2015

Testiranje motorja, nadgrajenega s tehnologijo "Slavyanka". Metro v Sankt Peterburgu, oktober 2015

Po naročilu proizvodno-tehničnega oddelka podzemne železnice v Sankt Peterburgu so zaposleni v elektromehanski službi s pomočjo varčne tehnologije "Slavyanka" posodobili nedelujoči elektromotor prezračevalne enote močnega prezračevanja predora.

Namen preskusov je ugotoviti spremembe v delovanju motorja po opravljeni modifikaciji.

Tip elektromotorja, ki so ga popravili leta 1975, je 5AM280S8Y3. Njegova moč pred okvaro je bila 55 kW, tok - 108 A, frekvenca vrtenja - 740 vrt / min, napetost - 380 V.

Po popravilu je bil eksperimentalni motor nameščen v enoti V-1. Kot rezultat preskusov je komisija določila naslednje tehnične karakteristike nadgrajenega motorja z navitjem "Slavyanka": obratovalni tok je bil 48 A; zagonski tok je dosegel 359 A.

Testiranje je potrdilo, da sprememba elektromotorjev z uporabo tehnologije Duyunova povečuje njihovo energetsko učinkovitost.

Dokument, ki pojasnjuje potek in rezultate preizkusov, je na voljo tukaj https://drive.google.com/drive/u/0/folders/1ful8GH2DhtwOOA8p2cGIc3J3OxRrXRkd?ths=true

-

Ruska tovarna za proizvodnjo prezračevalnih sistemov, 2016

Primerjalni testi elektromotorjev. Tovarna za prezračevalne sisteme, Rusija, oktober 2016

Namen preskusov je primerjati tehnične značilnosti dveh asinhronih elektromotorjev AIR80A4 z navitji tipa "Zvezda" in "Slavyanka".

Rezultati testiranja posodobljenega motorja s kombiniranimi navitji v primerjavi z običajnim so pokazali zmanjšanje porabe energije motorja zaradi skoraj popolne odsotnosti reaktivne komponente.

Zaradi uporabe varčne tehnologije "Slavyanka" so se tehnične značilnosti

elektromotorja spremenile na naslednji način:

- faktor moči se je povečal z 0,77 na 0,99;

- s povečanjem obremenitve na gredi se je poraba energije povečala z 1,1 na 2,23 kW;

- najvišja temperatura ohišja motorja z navitjem "Slavyanka" je bila 74 ° C,

pri 105°С, ki so dovoljene za razred toplotne odpornosti izolacije "F" navitij.Moč 2,2 kW, zabeležena za modernizirani motor, je nominalna za motorje podobnega tipa s 4 pari polov in višino rotacijske osi 90 mm, tj. naslednja stopnja na lestvici velikosti.

Poročilo o testiranjih je na voljo tukaj https://drive.google.com/file/d/1ImngEFWJFqXGn_FZh2rvYCgemDfrve_S/view

-

Laboratorij "Sovelmash", Zelenograd, 2019

Testiranje elektromotorjev DA-90S in DA-100S L. Laboratorij "Sovelmash", Zelenograd, 2019

Laboratorij "Sovelmash" je izvedel laboratorijske preskuse motorjev, nadgrajene v AS & PP Weihai: DA-90S in DA-100S L (razširjen).

Namen preskusov je potrditi deklarirane tehnične karakteristike elektromotorjev.

Med testiranjem so bili doseženi pričakovano dobri rezultati.

Oba motorja sta v nominalnem načinu pokazala do 90% učinkovitost, v številnih momentih pa je bila učinkovitost 85-88%. Motorji so brez težav zdržali daljše preobremenitve do 60 Nm.

Poročilo o preskusu motorja DA-90S - https://clck.ru/FVG4q

-

Univerza v Dusseldorfu, 2016

Testiranje Siemensovega motorja, nadgrajenega po "Slavyanki". Univerza v Dusseldorfu, januar 2016

Preskus je bil izveden v laboratoriju v Dusseldorfu na pobudo peterburškega podjetja "SPBEK"

Cilj testiranj je ugotoviti, kako bo navitje "Slavyanka" vplivalo na delovanje motorja znanega proizvajalca. Za navijanje so bili izbrani Siemensovi elektromotorji: originalni in previti z uporabo kombinirane tehnologije navijanja.

Med testiranjem je drugi motor pokazal večjo učinkovitost v celotnem obsegu. Ta test je pokazal, da je mogoče izboljšati tudi motorje s sprva dobrim izkoristkom, in sicer z menjavo navitij s kombiniranimi.

Poročila o preizkušanjih si lahko ogledate tukaj https://drive.google.com/file/d/1qBVDfIh_8Ehh2H65T8SLchvhZOW44OFC/view

Praktična uporaba tehnologije "Slavyanka"

-

KAMAZ z moderniziranim generatorjem

KAMAZ z moderniziranim generatorjem

Poleti 2017 so z uporabo tehnologije "Slavyanka" previli generator "KAMAZ" iz športnega kluba "KAMAZ-Master". Previjanje je povečalo moč generatorja za skoraj 30%.

Posodobljeni "KAMAZ" s posadko Antona Šibalova se je udeležil dirke Dakar-2017 v Južni Ameriki na progi Paragvaj - Bolivija - Argentina.

Ekipa "KAMAZ-Master" je bila zadovoljna z izboljšanjem, nato pa so bili generatorji preostalih avtomobilov previti za reli Dakar-2018!

Poleg tega je bilo odločeno, da motorje brisalcev vetrobranskih stekel dirkalnih tovornjakov KAMAZ previjemo nazaj na Slavyanko.

Posodobitev generatorjev "KAMAZ-Master" je izvedlo podjetje Electrocomplex, imetnik licence podjetja "ASiPP".

-

Električni avtomobil "ZAZ"

Električni avtomobil ZAZ-966 z motorjem Duyunova

Avtomobil Zaporožec je bil posebej za maraton električnih avtomobilov Kijev-Monte Carlo leta 2015 opremljen z motorjem, posodobljenim s tehnologijo "Slavyanka".

V Odesi so ustanovitelji projekta Ecofactor v 3 tednih popolnoma posodobili avto, zamenjali notranjost, nespremenjeno so pustili samo karoserijo.

V okviru maratona je odeska posadka prečkala 10 držav in prevozila skoraj 3000 km razdalje. Na enem od odsekov poti je ZAZ uspel prehiteti električni avtomobil Tesla. Z električnim avtomobilom na cesti ni bilo težav, z izjemo manjših napak, ki so jih hitro odpravili.

Zaporožec je v cilj prišel peti v skupni razvrstitvi in drugi med posodobljenimi električnimi vozili, električni avtomobil Odessa pa je osvojil tudi nagrado občinstva. Poleg tega je na ZAZ opozoril tudi sam ustanovitelj maratona, princ Monaka Albert, ki je opazil originalno zunanjost ukrajinskega avtomobila.

Promocijski video o posodobitvi ZAZ - https://www.youtube.com/watch?v=m8uGFK2H-H8&t=40s

-

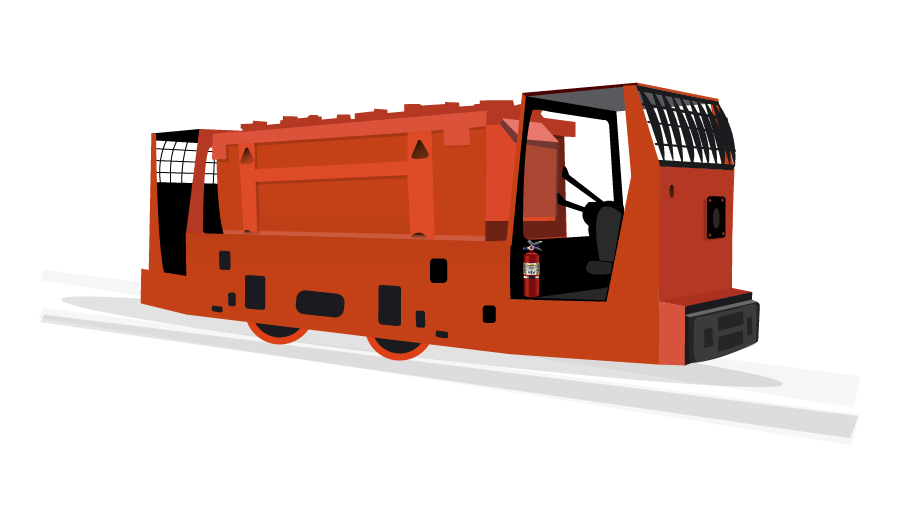

Električna rudniška lokomotiva "Era"

Električna rudniška lokomotiva Era

Električna lokomotiva Era - vozilo, ki se uporablja za prevoz blaga v rudnikih na ozkotirni železnici.

Leta 2013 je bil v Donecku namesto standardnega DRT-13 nameščen motor Eru, dimenzije 112, nadgrajen s tehnologijo "Slavyanka", prav tako pa tudi krmilnik znamke Curtis.

Med testiranji je električna lokomotiva dosegla naslednje rezultate: potegnila je 11 vozičkov s premogom, medtem ko je prejšnji motor potegnil 5, dosegla je hitrost - 12 km / h na ravni površini in 7 km / h v porastu, pri prevozu 100 ton premoga se motor kljub dvojnemu povečanju obremenitve ni pregrel.

Razvojni produkt Duyunova je podvojil produktivnost dela rudarjev iz Donecka, hkrati pa znatno zmanjšal porabo energije. Strokovnjaki so opazili tudi znatno zmanjšanje visokofrekvenčnih harmonikov in reaktivnih komponent v javnih elektroenergetskih omrežjih, iz katerih so se napajale vlečno-spustne podpostaje.

-

"Tavria" z motorjem Duyunova

Tavria z motorjem Duyunova

Leta 2014 je Igor Korkhov, prebivalec regije Belgorod, posodobil splošni industrijski motor dimenzije 100 in ga posodobil s pomočjo tehnologije "Slavyanka". Zaradi posodobitve je motor z razmeroma majhno težo 29 kilogramov postal desetkrat močnejši.

Pred posodobitvijo je bila moč motorja 4 kW, nato pa se je povečala na 12-13 kW, največ pa je motor začel proizvajati do 50 kW.

"Igor Korkhov je avtomobil Tavria opremil z izboljšanim motorjem. Težek avtomobil je brez težav speljal tako v prvi kot v tretji hitrosti, medtem ko se je skoraj neslišno premikal. Največja hitrost avtomobila je bila 110 km / h, brez polnjenja pa je prevozil približno 100 kilometrov."

Igor Korkhov je Tavrijo začel posodabljati v začetku 2000-ih. Na avtomobilu je bil že nameščen elektromotor, a inženir ni bil zadovoljen s hitrostjo, ki ni dosegala več kot 50 km / h. Zato je Tavrijo najprej oskrbel z ameriškim kolektorskim elektromotorjem, nato pa z motorjem s kombiniranimi navitji v kompletu s krmilnikom Curtis.

Tavria deluje do danes, že z novim lastnikom. In danes je Igor Korhov član ekipe Duyunova in dela za podjetje "Sovelmash" v Zelenogradu.

Video o Tavriji na Life news - https://www.youtube.com/watch?v=RhPMZyUspeI

-

Trolejbus v Kijevu

Trolejbus v Kijevu

Leta 2014 so v Kijevu na osnovi podjetja KievPasTrans izvedli teste trolejbusa z motorjem, nadgrajenim po tehnologiji "Slavyanka".

Spremenjen pogon je povečal hitrost trolejbusa in zmanjšal porabo energije. Projekt je bil zaključen zaradi neugodnih dogodkov v Ukrajini.

-

Citroёn z motorjem Duyunova

Citroёn z motorjem Duyunova

Partner Dmitrija Dujunova, Viktor Arestov, je leta 2017 v Nemčiji v stari model električnega Citroëna vgradil motor, posodobljen po tehnologiji "Slavyanka".

Posodobljeni električni avtomobil je opazovalce presenetil s hitrim speljevanjem, z visoko hitrostjo in okretnostjo. Polnjenje avtomobila traja le eno uro.

Specifikacije Citroëna po nadgradnji motorja:

Teža - 750 kg

Baterija - 14 kWh

Krmilnik Curtis 1238 96 V.

Povprečna poraba polnjenja - 9,6 kWh na 100 km

Mestna poraba - 7,2 kWh na 100 km

Razdalja z enim polnjenjem - do 180 km

Največja hitrost - 130 km / hZahvaljujoč posodobitvi elektromotorja s tehnologijo "Slavyanka" je Citroën uspel doseči bistveno izboljšanje ključnih lastnosti.

Videoposnetek Viktorja Arestova, ki je posodobil električni avtomobil https://www.youtube.com/watch?v=RDdM2bclpKg&t=5s

Ena iz reportaž o Citroenu v nemščini https://www.youtube.com/watch?v=WtVqu0rLADw

-

Tovornjak Denzel Pickman

Tovornjak Denzel Pickman

Električno vozilo Pickman je vozilo z nosilnostjo do 500 kg. Uporablja se pri premikanju po majhnih površinah: v kmetijstvu, turizmu ali proizvodnji.

Septembra 2017 je bil na tovornjak nameščen električni motor, nadgrajen s tehnologijo "Slavyanka", ki je po velikosti in teži manjši od običajnega motorja. Zahvaljujoč novemu motorju:

hitrost vozila se je povečala; življenjska doba baterije se je podaljšala.

Kasneje je Denzel Pickman namestil močnejše motorje s kombiniranimi navitji, ki jih je ASPP Weihai posodobil s tehnologijo Slavyanka.

Leta 2018 je bil tovornjak preizkušen z motorjem DA-90S.

Leta 2019 - z motorjem DA-100S in novo litijevo baterijo (84 Ah) namesto svinčene baterije (100 Ah). Z njimi je električni avtomobil prikazal naslednje kazalnike:

hitrost - 65 km / h, dosežena razdalja - 100 km, pri vožnji s povprečno hitrostjo približno 50 km / h.

Video iz testiranja Pickman Challenge - https://www.youtube.com/watch?v=dLcZMtuVOjI&t=9s

-

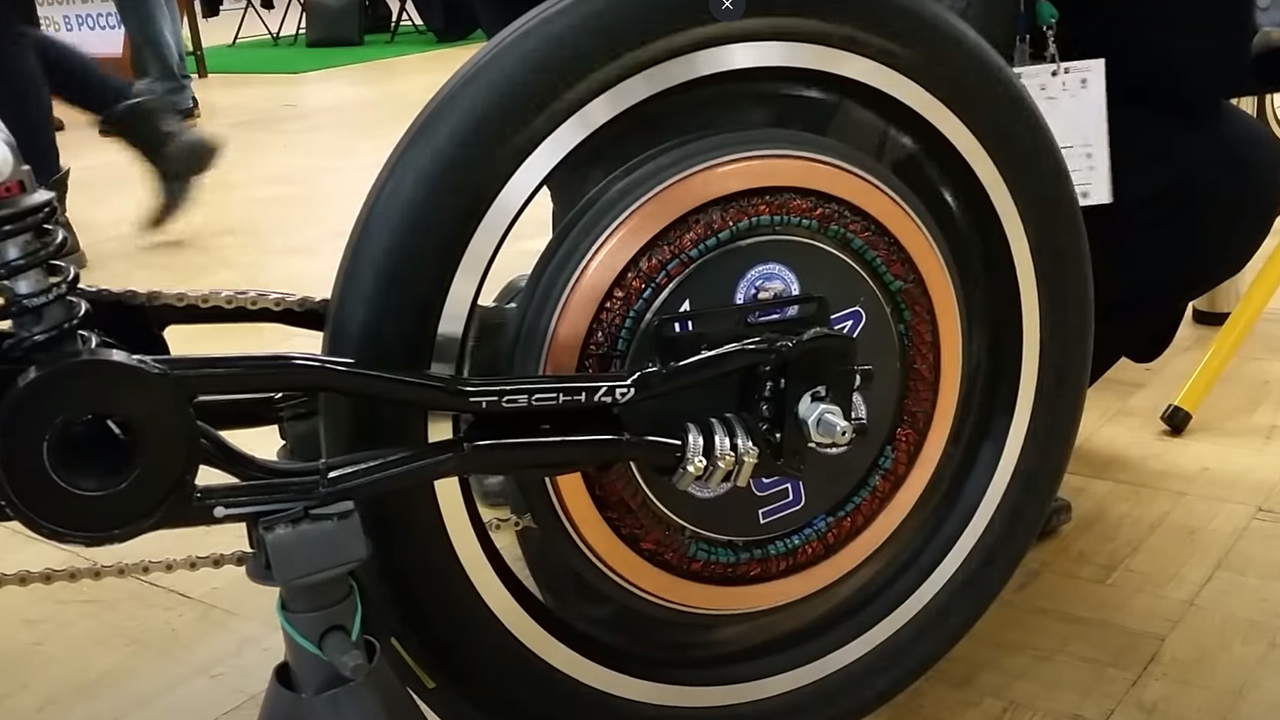

Električni moped Irbis Grace z motorjem v pestu, dimenzije 318

Električni moped Irbis Grace z motorjem v pestu, dimenzije 318

Skuter Irbis je bil posodobljen leta 2016. Na vozilo je bil nameščen eden prvih prototipov Duyunova, motor v pestu, dimenzije 318. Poleg tega je bila zamenjana zadnja nihajna ročica, na krmilni odsek pa dodana ročica za regenerativno zaviranje. Vsi tovarniški električni in krmilni sistemi električnega mopeda so bili ohranjeni.

Že prve testne vožnje so pokazale, da je Irbis postal bolj vodljiv, lažje se je premaknil z mesta in dosegel odlično hitrost. Med testno vožnjo po podeželski cesti je električni skuter lahko pospešil do 70 km / h.

Vrhunec testiranj: Irbis Grace je Nivo (1500 kg) premaknil z mesta in jo povlekel za seboj ter s tem izkazal svojo moč in vzdržljivost.

Video, v katerem Evgenij Duyunov govori o skuterju Irbis Grace z motorjem v pestu dimenzije 318 - https://www.youtube.com/watch?v=WH3vAeIRElE&t=39s

-

Električni avtomobil Renault Kangoo

Električni avtomobil Renault Kangoo

Leta 2015 je član ekipe Duyunov, Viktor Arestov, po tehnologiji Slavyanka predelal motor avtomobila Renault Kangoo, katerega električni motor se je močno pregreval. Posledično se je motor prenehal segrevati, prevožena razdalja električnega vozila pa se je povečala za 20%.

Kasneje se je še naprednejša različica Renault Kangooja udeležila 7 razstav v Monaku in na jugu Francije ter s svojimi karakteristikami navdušila obiskovalce in strokovnjake, tj.: s pospeškom z mesta v 3. ali 4. prestavi in vožnjo v klanec v 4. prestavi.

Tehnični podatki Renault E-Kangoo:

Teža vozila: 1560 kg

Krmilnik: Curtis 1238-7601 650 A

Baterije: 33 x WINSTON WB-LYP200AHA 3,2 V (33 x 3,2 V x 200 AHA = 21,120 kWH)

Motor "Slavyanka": dimenzije 112, teža 60 kg

Moč: maks. 57 kW (omejeno s krmilnikom); nazivna: 35 kW

Število vrtljajev motorja: do 9000 (omejeno s krmilnikom Curtis na 8000 vrt / min)

Največja hitrost: do 150 km / h

Največja razdalja: do 210 km pri 50 km / h

Poraba pri 50 km / h: 5,7-6,2 kWh; pri 80 km / h: 12,7 kW (4x4 pogon na vsa kolesa)

Čas pospeševanja 0-100 km / h: 14 sek.Električni avtomobil vozi še danes, po svojih parametrih pa prekaša istovrstne avtomobile kot sta denimo Renault in Citroёn.

Renault Kangoo v akciji - https://www.youtube.com/watch?v=6bgLduo-xWs&t=1s

-

Električni avtomobil Renault Twizy

Električni avtomobil Renault Twizy

Originalni motor električnega avtomobila Renault Twizy je bil leta 2017 v Nemčiji previt s pomočjo tehnologije "Slavyanka".

Preizkusi Twizyja so se začeli z zastarelim petletnim akumulatorjem, ki pa ni oviral izboljšav zmogljivosti vozila.

Po posodobitvi je električni avtomobil navdušil s tehničnimi lastnostmi:

- potovalna razdalja se je povečala za več kot 20%,

- moč motorja se je povečanla na 18 kW,

- motor se ni pregrel, ostal je nekoliko topel.Električni avtomobil je bil aprila 2017 predstavljen na razstavah EVER in Top Mark v Monaku. Prisotne je presenetil s prostim pretokom v prometu in prevoženo razdaljo.

Danes se Twizy nahaja pri "Sovelmash" v Zelenogradu in čaka na nadaljnje izboljšave tehničnih parametrov. Na električni avtomobil je predvidena vgradnja nove baterije, ki tehta le 60 kg (namesto 120 kg stare litij-fosfatne baterije) in je dvakrat močnejša od predhodne.

-

Električni avtomobil Zetta

Električni avtomobil Zetta

Eden od najpomembnejših dogodkov pri uporabi motornih koles Duyunova je bil avtomobil Zetta.

Zetta (takrat še vedno El-Panda) je bila prvič predstavljena septembra 2017 na razstavi v Uljanovsku, kjer jo je izpostavil predsednik Rusije.

Pri ustvarjanju električnega avtomobila so bili uporabljeni motorji v pestu, dimenzije 318, z maksimalno močjo do 18,1 kW, z navorom, ki je približno 200 Nm. To pomeni, da motorji v pestu skupaj razvijejo 72,4 kW moči (98 KM) in 800 Nm navora.

Vsak motor v pestu ima svoj krmilnik, tako da lahko električni avtomobil vozi tako na pogon na vsa kolesa kot na sprednji in zadnji pogon. Skupaj so krmilniki sinhronizirani glede na navor, to pa pozitivno vpliva na kakovost vožnje.

Litij-ionske baterije Zetta odlikuje zmogljivost 10 kW * h, dajejo za 200 km energije, brez dodatnega polnjenja, pri tem ko je njihova poraba enaka 40 Wh na kilometer.

Zasnova šasije je univerzalna, torej se lahko uporablja za različne tipe karoserij.

Intervju z Evgenijem Duyunovom o Zetti - https://www.youtube.com/watch?v=z0RYgIYIzOc&t=1s

Predstavitev Zette - https://www.youtube.com/watch?v=V8GnFw87bAk&t=5s

-

Motor v pestu, dimenzije 186

Motor v pestu, dimenzije 186

Asinhroni motor v pestu, ki je v tem oziru prvi na svetu, je eden izmed najbolj priljubljenih izumov ekipe Dmitrija Duyunova. Gre za motor, ki je vgrajen v kolo električnega vozila, pa naj bo to električno kolo, skuter, motocikel ali avto. Motor v pestu Duyunova uporablja tehnologijo kombiniranega navijanja "Slavyanka".

Analogi motorja v pestu Duyunova so BLDC motorji, ki delujejo na osnovi magnetov. Za njihovo izdelavo so potrebne redke zemeljske kovine, ki jih je količinsko dovolj samo na Kitajskem. Če upoštevamo, da priljubljenost električnih vozil v svetu vsako leto narašča, potem lahko rečemo, da asinhronski motor v pestu ni le analog, temveč polnopravna, učinkovitejša in cenovno ugodna zamenjava za kitajske BLDC motorje.

Dela na motorjem v pestu velikosti 186 ("Kolobok") so se začela 4. februarja 2015. Prvotno je bil zasnovan za napravo za poganjanje invalidskega vozička: napravo, ki zagotavlja bolj funkcionalno premikanje invalidov. Kasneje je bil "Kolobok", dimenzije 186, preizkušen na kolesu.

Motor v pestu se ne pregreje, nanj ne vplivajo zunanji dejavniki, ni občutljiv na vlago, prah in umazanijo, prevozna sredstva s takim motorjem so hitra.

Lastnosti motorja:

teža - 8 kg, <br>največja učinkovitost - 94%, <br>največja hitrost kolesa z motorjem v pestu je 101 km / h, <br>začetni navor pri startu je 52 Nm, <br>navor - 200 Nm <br>največji obratovalni moment je 76 Nm. <br>največja moč - 20 kW,

Motorje v pestu Duyunova odlikuje moč in dolga življenjska doba, njihovi proizvodni stroški so za 30% nižji, poleg tega pa so tudi cenejši za vzdrževanje. Vozila z motorjem v pestu kažejo povečano število prevoženih kilometrov.

Kasneje je bil zasnovan motor v pestu dimenzije 318 in mase 18 kg. Dimenziji 186 in 318 sta najmanjši in največji, Duyunova ekipa pa pripravlja vmesno različico. Med testiranjem in utekanjem so bili motorji v pestu preizkušeni na različnih kolesih: "Gran", "Versija, El Moto, Denzel Sparta, Denzel Escort

-

Kotni brusilnik

Kotni brusilnik

Inženirji družbe "Sovelmash" so kotni brusilnik UShM 230/2100M nadgradili z vgradnjo asinhronega kratkostičnega pogona, zasnovanega na osnovi tehnologije kombiniranega navijanja.

Nato so bili v laboratoriju "Sovelmash" izvedeni primerjalni testi delovanja standardnih in modificiranih strojev. Preizkusi so pokazali, da kotni brusilniki z motorjem Duyunova delujejo mehkeje: to se vidi tako pri vrtenju, kot pri ravni hrupa in pri kakovosti samega rezanja.

Poleg tega so bile zabeležene naslednje značilnosti:

- prosti tek v običajnem stroju je višji kot pri stroju z asinhronim pogonom, toda med obremenitvijo je razlika med njima popolnoma izravnana; - pri različici s "Slavyanko" je bistveno manj komponent, kar vpliva hitrejše rezanje in podaljšanje življenjske dobe kotnih brusilnikov; - teža in raven hrupa kotnega brusilnika z asinhronim pogonom sta nižja kot pri konkurentu.

Izboljšane lastnosti kotnega brusilnika s "Slavyanko" povečajo produktivnost in stopnjo udobja pri delu z njim.

Dmitrij Duyunov o razvoju specializiranega asinhronega pogona, zasnovanega za uporabo v električnih orodjih - https://youtu.be/ltLRWSdZBIo

Primerjalne teste kotnih brusilnikov s “Slavyanko” in klasičnimi kotnimi brusilkniki si oglejte tukaj - https://youtu.be/oiavBAL9OXo

Majhna serijska proizvodnja

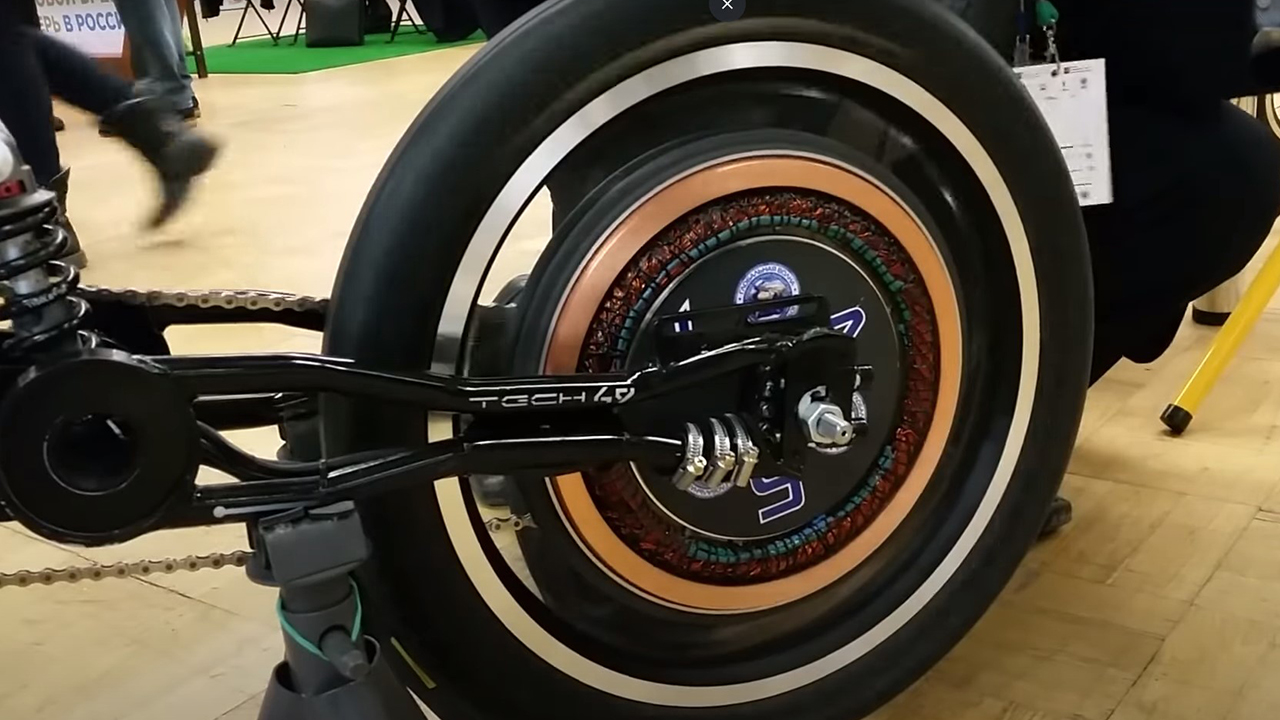

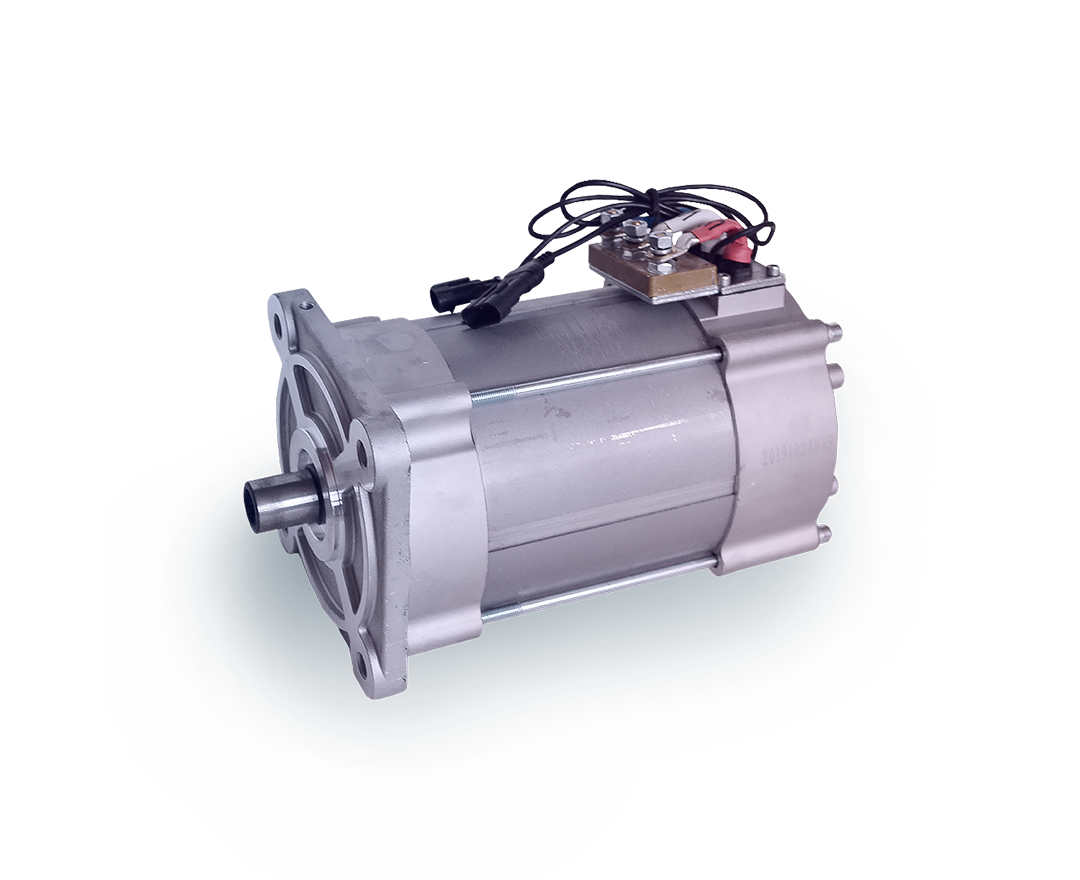

Elektromotor DA-90S

Asinhroni motor, prirejen po tehnologiji Slavyanka, Kitajskega proizvajalca

- Tip motorja: asinhroni motor

- Nazivna moč: 3 kW (3300 vrt / min)

- Maksimalna moč: 9,5 kW

- Stalni tok (največja vrednost): 60 A (fazni tok)

- Temenski tok: 350 А

- Nazivna napetost: 72V

- Največja hitrost: 5000 vrt / min

- Učinkovitost: 92%

- Navor (največja vrednost): 74 Nm (na gredi)

- Teža: 10,5 kg

- Brez magnetnega upora

- Povečana učinkovitost v celotnem območju obremenitve

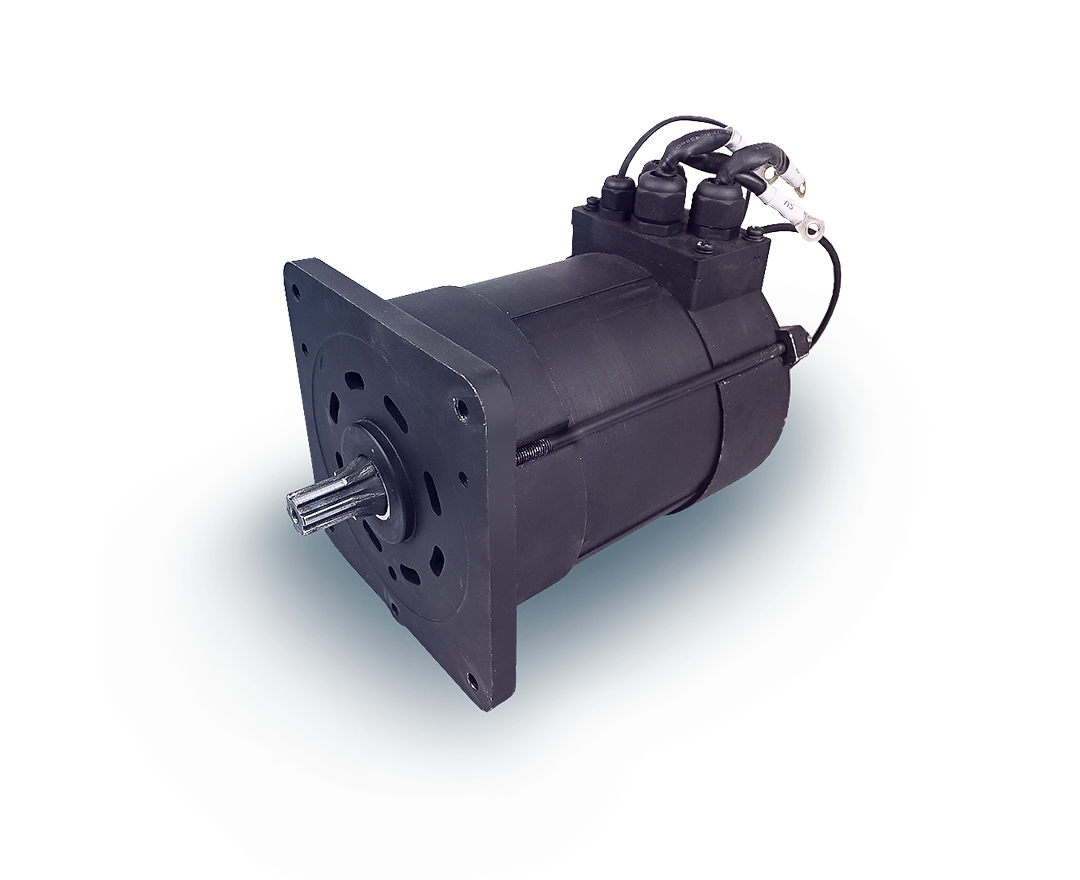

Elektromotor DA-90SM

Asinhroni motor, prirejen po tehnologiji Slavyanka, Kitajskega proizvajalca

- Tip motorja: asinhroni motor

- Nazivna moč: 4 kW (3300 vrt/min)

- Konična moč: 10 kW

- Trajni tok (največja vrednost): 80 A (fazni tok)

- Temenski tok: 350 А

- Nazivna napetost: 72V

- Največja hitrost: 7000 vrt / min

- Učinkovitost: 92%

- Navor (največja vrednost): 74 Nm (na gredi)

- Teža: 11,2 kg

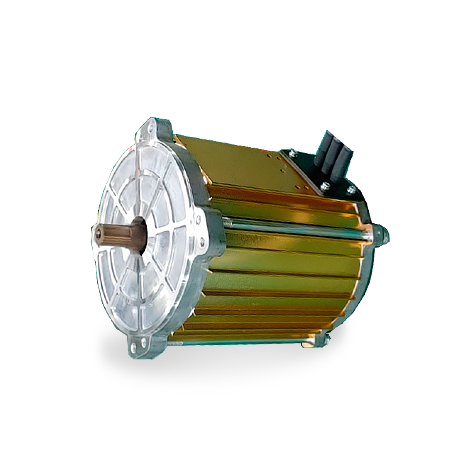

Elektromotor DA-95S

Asinhroni motor, prirejen po tehnologiji Slavyanka, Kitajskega proizvajalca

- Tip motorja: asinhroni motor

- Nazivna moč: 5 kW (3300 vrt/min)

- Maksimalna moč: 14,5 kW

- Navor pri 275A–83,3 N.m.

- Trajni tok (največja vrednost): 80 A (fazni tok)

- Temenski tok: 350 А

- Nazivna napetost: 72V

- Največja hitrost: 7000 vrt / min

- KPD: 95 %

- Navor (največja vrednost): 106 Nm (gred)

- Teža: 14 kg

Elektromotor DA-112S

Asinhroni motor, prirejen po tehnologiji Slavyanka, Kitajskega proizvajalca

- Tip motorja: asinhroni motor

- Nazivna moč: 7 kW (3200 vrt / min)

- Maksimalna moč: 21 kW

- Konstantni tok: 120 A (fazni tok)

- Maksimalni tok: 550 A

- Nazivna napetost: 72V

- Največja hitrost: 7500 vrt/min

- Učinkovitost: 91%

- Navor (največja vrednost): 151 Nm (gred)

- Teža: 23 kg

Elektromotor DA-112SL

Asinhroni motor, prirejen po tehnologiji Slavyanka, Kitajskega proizvajalca

- Tip motorja: asinhroni motor

- Nazivna moč: 12 kW (3200 vrt / min)

- Maksimalna moč: 36 kW

- Stalni tok: 260 A (fazni tok)

- Temenski tok: 650 А

- Nazivna napetost: 72V

- Največja hitrost: 7000 vrt / min

- Učinkovitost: 93%

- Navor (največja vrednost): 210 Nm (na gredi)

- Teža: 35 kg

- Brez magnetnega upora

- Povečana učinkovitost v celotnem območju obremenitve

SPECIFIKACIJA za skuter z električnim motorjem DA-90S

Električni motocikel Denzel Liberty z motorjem DA-95S

Električni motocikel SUZUKI AX-100 z električnim motorjem DA-90S

Električni motocikel Cafe Racer z motorjem DA-95S