Tests of Duyunov's technology

We continue telling you about the tests of Duyunov's technology held earlier.

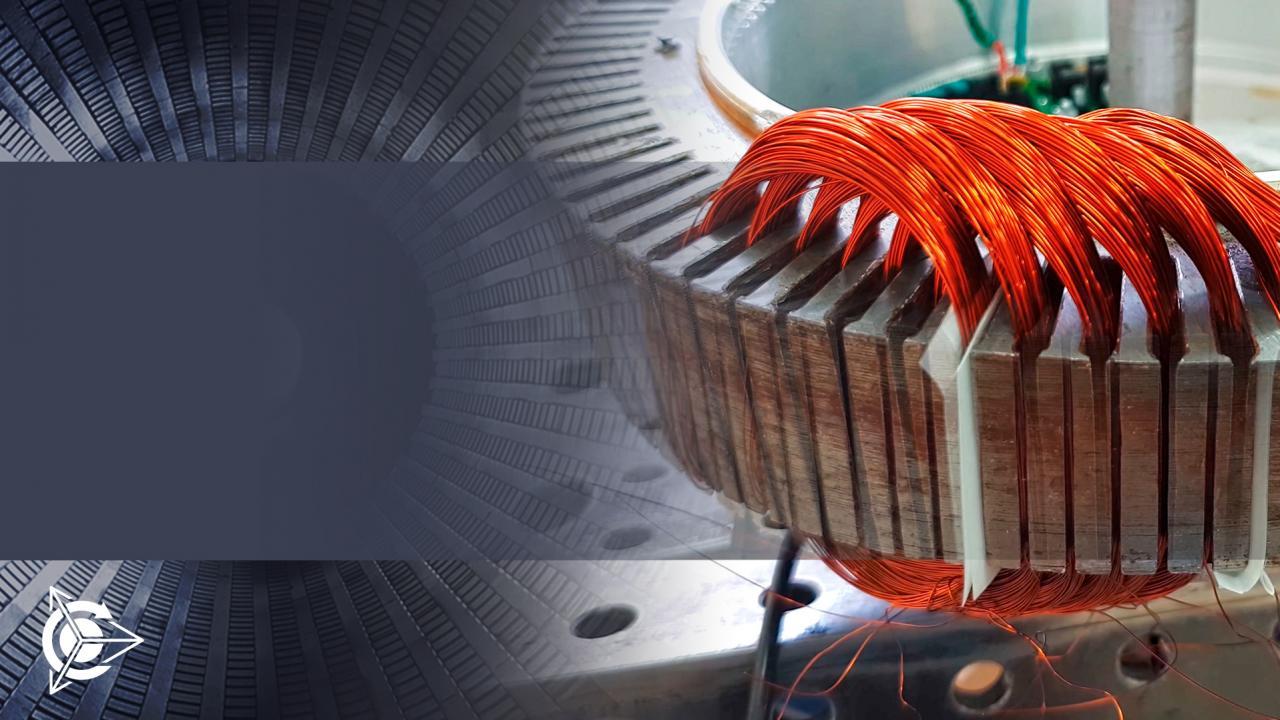

Testing the modernized motor for a drain pump

In 2016 the engineers of a Russian plant modernized by their own efforts the induction motor 5AI160M2U2 with the power of 18.5 kW installed into a drain pump. In the course of the repair works the old winding was removed by heat treatment and the motor was rewound using the patented "Slavyanka" technology.

The tests of the experimental motor demonstrated the following changes of its performance specifications as compared against the parameters before the modernization:

• Before the repair the electric motor 5AI160M2 was designed for operating at the voltage of 660V but now it's powered by 380V.

- At the voltage of 500V provided in the lab conditions the open-circuit current reduced on average by 12% from 27.3 A to 24.0 A.

- When operating at 380V the open-circuit current reduced by 3% and under load - by 2%.

- After rewinding the pump productivity increased which resulted in the motor workload reduction by 8% and the reduction of consumed power by 12 %. The time of the pump operational cycle reduced by 39 seconds.

- The consumed power at the tank pumpout amounted to 2.573 kW, after the winding it reduced to 2.3368 kW. The implementation effect was estimated as 10 %.

The protocols and explanations to them are provided in Russian - https://clck.ru/FPKMs

The comparative test of the electric motors at the ventilation system production site

In 2016 on a major Russian plant producing ventilation systems, the comparative testing of two induction electric motors AIR80A4 with the "Star" and "Slavyanka" winding types was held. The results of testing the modernized motor as compared against the regular one demonstrated the reduction of the motor consumed power due to practically no reactance component.

As a result of applying the energy saving "Slavyanka" technology the electric motor performance specifications changed in the following way:

• The power factor increased from 0.77 to 0.99.

• When increasing the shaft load the consumed power increased from 1.1 to 2.23 kW.

• The maximum temperature of the motor case with the "Slavyankа winding was 74°С with the admissible value of 105°С for winding insulation thermal endurance class “F”.

The chief executive officer of the company who had conducted the comparative test said that the recorder power of 2.2 kW was nominal for similar type motors with 4 pairs of poles and rotation axis height of 90 mm which is the next frame size scale pitch.

The corresponding document in Russian is available here - https://clck.ru/FPKMY

The information source in Russian - http://dvigatel.myfor.ru/viewtopic.php?f=213333t=410